Energy Saving and Emission Reduction Promoting Sustainable Development of Hong Kong

Continuous increase of greenhouse gas emission intensifies global warming and climate change. Since 2007, the Drainage Services Department (DSD) has been a member of the Interdepartmental Working Group on Climate Change, set up by the Environment Bureau for formulating policies and measures to reduce greenhouse gas emissions and combat climate change. In support of “Hong Kong’s Climate Action Plan 2030+” (“Action Plan”) published by the Government in 2017 that encourages extensive use of renewable energy (RE), DSD has actively implemented energy-saving initiatives and deployed additional resources in promoting and adopting renewable energy technologies on a wider and larger scale in its existing and new facilities to reduce carbon emissions and protect the environment for achieving sustainable development. The renewable energy systems generate electricity and heat for the facilities in DSD’s plants. To help with building a cleaner and more sustainable environment, DSD will continue with the efforts to adopt various technologies, to harness renewable energy, including solar power, hydropower and biogas.

Implemented Measures for Saving Energy and Harnessing Renewable Energy

At present, RE installations in DSD’s plants generate over 28 million kilowatt-hours of electricity per annum, constituting around 9% of DSD’s annual energy demand. In terms of efficiency, DSD’s current annual RE contribution is equivalent to the energy consumption of 5,600 households and can reduce about 19,600 tonnes of carbon dioxide (CO2) emission a year.

In addition, DSD obtained a capital funding of $248 million in total for 12 major renewable energy projects in 2017–18 and 2018–19 to generate a total of 6 million kilowatt-hours of electricity a year. These projects are under construction. Besides, DSD has been optimising the operation of various sewage treatment works (STWs) and sewage pumping stations (SPSs), including replacement of ageing equipment with more efficient energy saving units. The items being replaced include the plants’ air blowers, lighting systems, pumps, and screens. With these RE projects and energy saving initiatives, DSD has set an electricity saving target of 4% by 2024-25, with respect to the baseline electricity consumption of about 315 million kilowatt-hours in 2018-19. DSD is striving to achieve this target.

Solar Energy – Installation of Photovoltaic Panels in Sewage Treatment Facilities

Over the years, DSD has endeavoured to utilise the open space in STWs and SPSs to install photovoltaic (PV) system. As at end March 2019, DSD has installed PV panels at 15 STWs and 13 SPSs to harness solar energy by maximising the use of the plants’ space. The major plants include Sha Tin STW, Yuen Long STW, Shek Wu Hui STW and Stonecutters Island STW. Notably, the Solar Farm at Siu Ho Wan STW commissioned at the end of 2016, comprises over 4,200 units of polycrystalline PV panels which can generate as much as 1.1 million kilowatt-hours of electricity annual, making it the largest PV system among the Hong Kong SAR Government facilities at present. In 2018-19, the total PV system of DSD is generating about 1.12 million kilowatt-hours of electricity.

DSD will continue to extend the use of solar power in its facilities and install more PV panels at various pumping stations and STWs. The total generation capacity of the new systems is about 0.9 megawatts, including the installation of thin-film PV panels above the sedimentation tanks at Stonecutters Island STW, fully utilising space to generate energy. It will become the largest thin-film solar system in Hong Kong, with a generation capacity of over 0.5 megawatts.

Hydroelectric Power– Hydro-turbine System at Stonecutters Island Sewage Treatment Works

After the commission of the Harbour Area Treatment Scheme Stage 2A, DSD installed a hydro-turbine system which utilises hydraulic energy from the flow of sewage to move the turbine and generate electricity for inhouse use at Stonecutters Island STW. It is a completely automated operation, regulating the generator speed according to the daily sewage flow rate in order to enhance its operating efficiency. The system commissioned in October 2018, with a design capacity of 23 kilowatts, it is expected to generate up to 120,000 kilowatt-hours of electricity a year. The system does not only save electricity costs, but also make good use of hydropower to reduce carbon emissions. In light of the high efficiency of this project, we plan on installing a second hydroturbine system at Stonecutters Island STW.

Waste to Energy

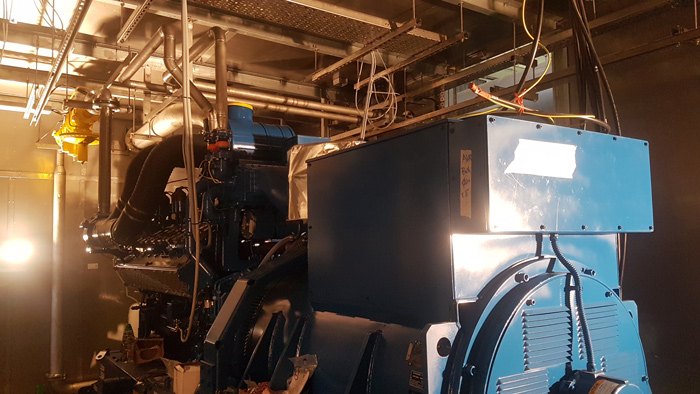

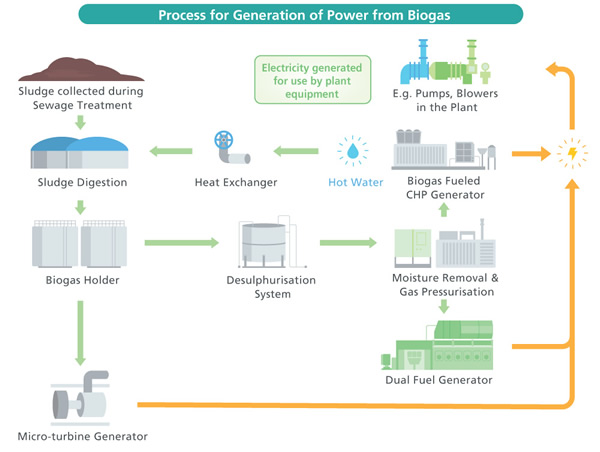

Sludge, a byproduct of sewage treatment process, produces biogas during anaerobic digestion. Biogas is a form of renewable energy which contains 65% methane (the remaining components mainly being carbon dioxide). DSD utilises combined heat and power (CHP) generators and gas-turbines that run on biogas to generate electricity and heat for in-house use. In 2018-19, the total electricity generation capacity of five CHP generators at Sha Tin STW, Tai Po STW and Shek Wu Hui STW is about 3.6 megawatts, while two gas-turbines at Sha Tin STW and Yuen Long STW have a total electrical generating capacity of 280 kilowatts. This year, the total energy generated by biogas at our STWs amounted to about 27 million kilowatt-hours.

To maximise the use of biogas generated during the sludge treatment process, we are installing additional CHP generators and gas-turbine systems at our STWs such as Sha Tin STW, Tai Po STW and Yuen Long STW. Once completed, it is anticipated that up to 5.4 megawatts of electricity can be generated. In addition, a tri-generation system, which generates heat, cooling and power has been installed at Sha Tin STW to increase the use of RE.

Way Forward – Food Waste and Sludge Co-digestion

To harness the synergy effects of the food waste and sludge co-digestion process, DSD has as worked in close collaboration with the Environmental Protection Department (EPD) to conduct a “Food Waste/Sludge Anaerobic Co-digestion Trial Scheme” in Tai Po STW. DSD is also planning to implement similar scheme at other suitable sewage treatment works on a larger scale.

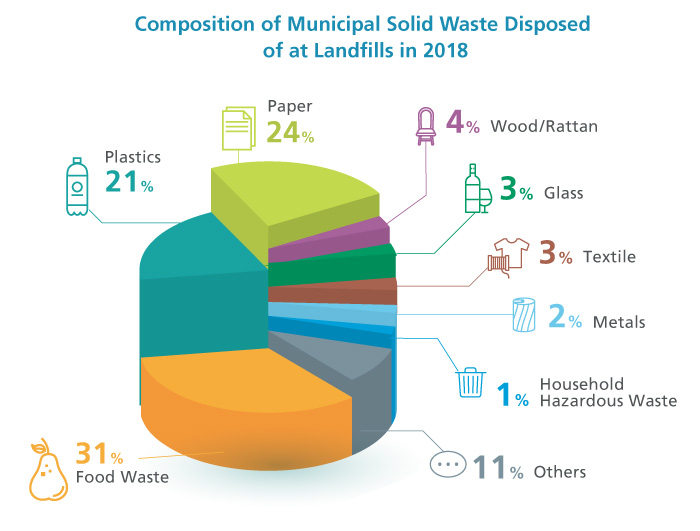

Food Waste and Sludge as Resources

Food waste is the largest component of municipal solid waste in Hong Kong. In 2018, 11,428 tonnes of municipal solid waste were disposed of at landfills each day, 3,565 tonnes of which were food waste. Sludge, a by-product of sewage treatment process is also solid waste. Currently, around 1,100 tonnes of sludge are taken to T • Park for incineration each day. On the one hand, food waste and sludge are solid waste; on the other hand, they are rich in energy resources.

Current Food Waste and Sludge Treatment Technologies

Anaerobic digestion refers to the microbiological breakdown of organic matter in the absence of oxygen. In this process, the odour and pathogens of waste and organic matter will be reduced, with biogas, a renewable energy source, generated as byproduct. Currently there are two Organic Resources Recovery Centres in Hong Kong adopted anaerobic digestion to treat food waste: Organic Resources Recovery Centre Phase 1 in Siu Ho Wan is currently in operation and Organic Resources Recovery Centre Phase 2 in Sha Ling is expected to be commissioned in 2022. These two centres are targeting 200 tonnes and 300 tonnes of food waste per day for treatment respectively and the digestate from these centres will then be further treated and turned into compost.

Currently, the sludge generated in the DSD’s secondary STWs is treated in the anaerobic digesters of the plant. In the anaerobic digestion process, the volume of sludge is reduced and biogas is produced for generating electricity and heat. In some countries, digested sludge will undergo further treatment for use as compost, while in Hong Kong the digested sludge is dewatered and then transported to T • Park for use as fuel in the incineration process, realising the concept of waste-of-energy. Heat produced from the incineration process is recovered and converted into electricity.

Anaerobic Co-digestion

Anaerobic co-digestion of food waste with sludge, hereinafter referred to as co-digestion, has been successfully applied overseas. Compared with anaerobic mono-digestion of food waste and sludge, co-digestion reduced solids content and increases the production of biogas, which can be used to generate energy and supplement the STWs’ energy consumption. With sufficient food waste and sludge, co-digestion has the potential to produce sufficient biogas to meet the energy demand of STWs. The Government is exploring the use of co-digestion in existing STWs to extend the network of organic resources recovery facilities, hence raising Hong Kong’s food waste treatment capacity.

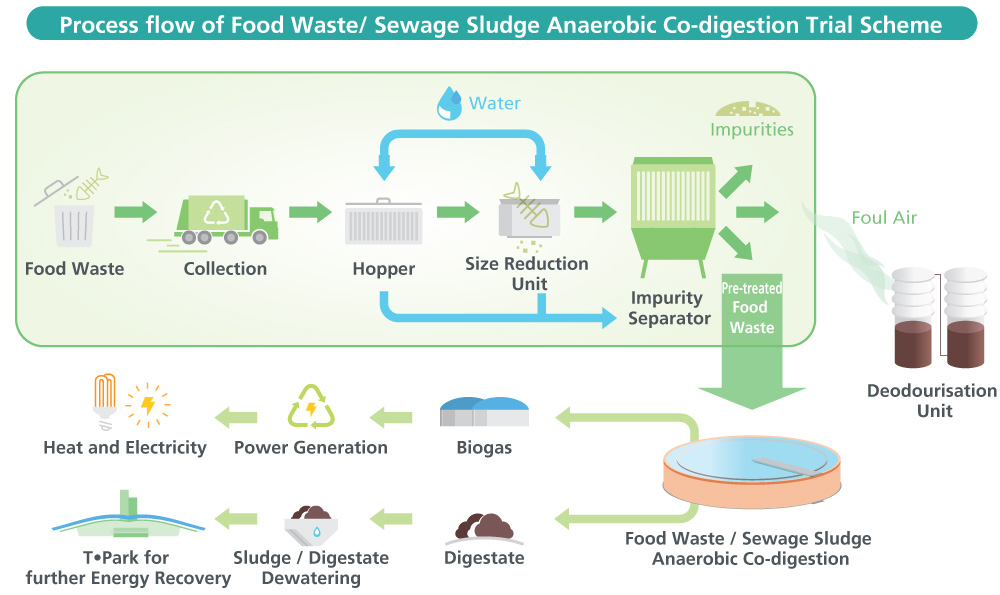

50-tonne Co-digestion Trial Scheme at Tai Po Sewage Treatment Works

The 2016 Policy Address announced that a co-digestion trial scheme will be conducted at Tai Po STW from 2019 onwards, treating 50 tonnes of food waste and sludge everyday. The trial scheme includes the construction of a food waste pre-treatment plant with a treatment capacity of 50 tonnes, located at the Shuen Wan Leachate Pre-treatment Works, adjacent to Tai Po STW and an operation trial scheme. The co-digestion trial scheme is collaboratively run by the DSD and EPD.

Under the trial scheme, EPD’s engineering works include construction of a food waste pre-treatment plant. Here, food waste is pre-treated to remove impurities before being mashed and turned into food pulp. DSD’s engineering works include modification of a digester designated to receive food waste. The modification works include replacement of the sludge mixer in the digester with a new mixer that is suitable for blending the sludge and food waste, which have a higher solids content, homogeneously. The trial scheme started in September 2019. During operation, EPD is responsible for collecting, delivering, pre-treating and pumping food waste to the designated anaerobic digester at Tai Po STW, while DSD is responsible for the operation of the digester and utilisation of biogas to generate heat and electricity for STWs’ use.

Benefits of 50-tonne Co-digestion Pilot Trial Scheme at Tai Po Sewage Treatment Works

DSD’s modification works for the designated digester under the trial scheme took only 12 months. With the food waste pre-treatment plant and STWs adjacent to each other, the trial scheme attains the benefits of co-location and co-treatment. Whether microorganisms in the digester can effectively degrade organic solids, depends on the nutrient balance in the digester. Compared with mono-digestion, co-digestion can enhance the degradation efficiency, hence decreasing solids content and boosting biogas yield. In Hong Kong, digested sludge will be dewatered and transported to T • Park to be used as fuel in the incineration process. Heat generated during the process will be recovered and converted into electricity. In this process, the dewatered digestate will become ash, meaning it volume will decrease by 90%. Consequently, precious landfill space can be saved.