Dear Harbour,

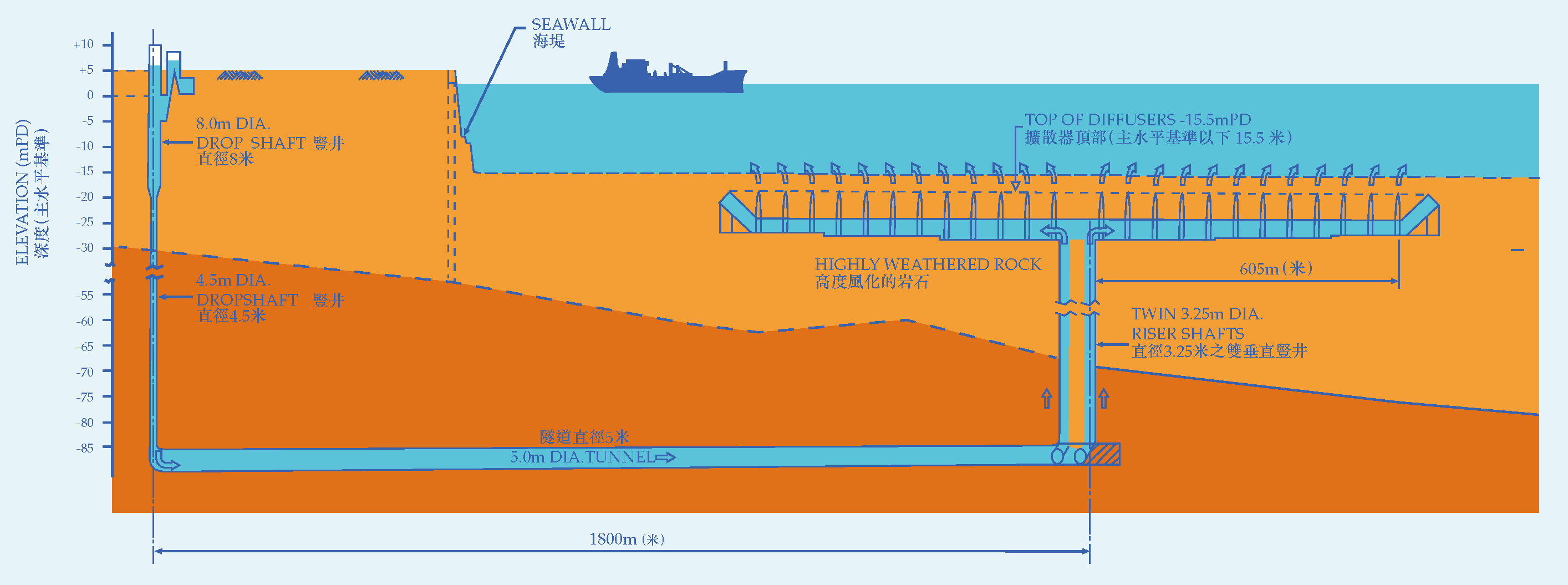

In our earlier letters, we shared with you how the HATS project began, why the centralised option was chosen, and how a labyrinth of deep sewage tunnels was successfully constructed despite enormous engineering difficulties. This crucial work took place from the early 1990s onwards as part of HATS Stage 1 to tackle increasingly serious pollution in your Harbour waters.

The centralised sewage treatment works on Stonecutters Island is the beating heart of HATS: fed by the deep tunnels that are its arteries, it treats the city’s sewage and discharges the treated sewage into the western approach of the Harbour.

Stonecutters Island

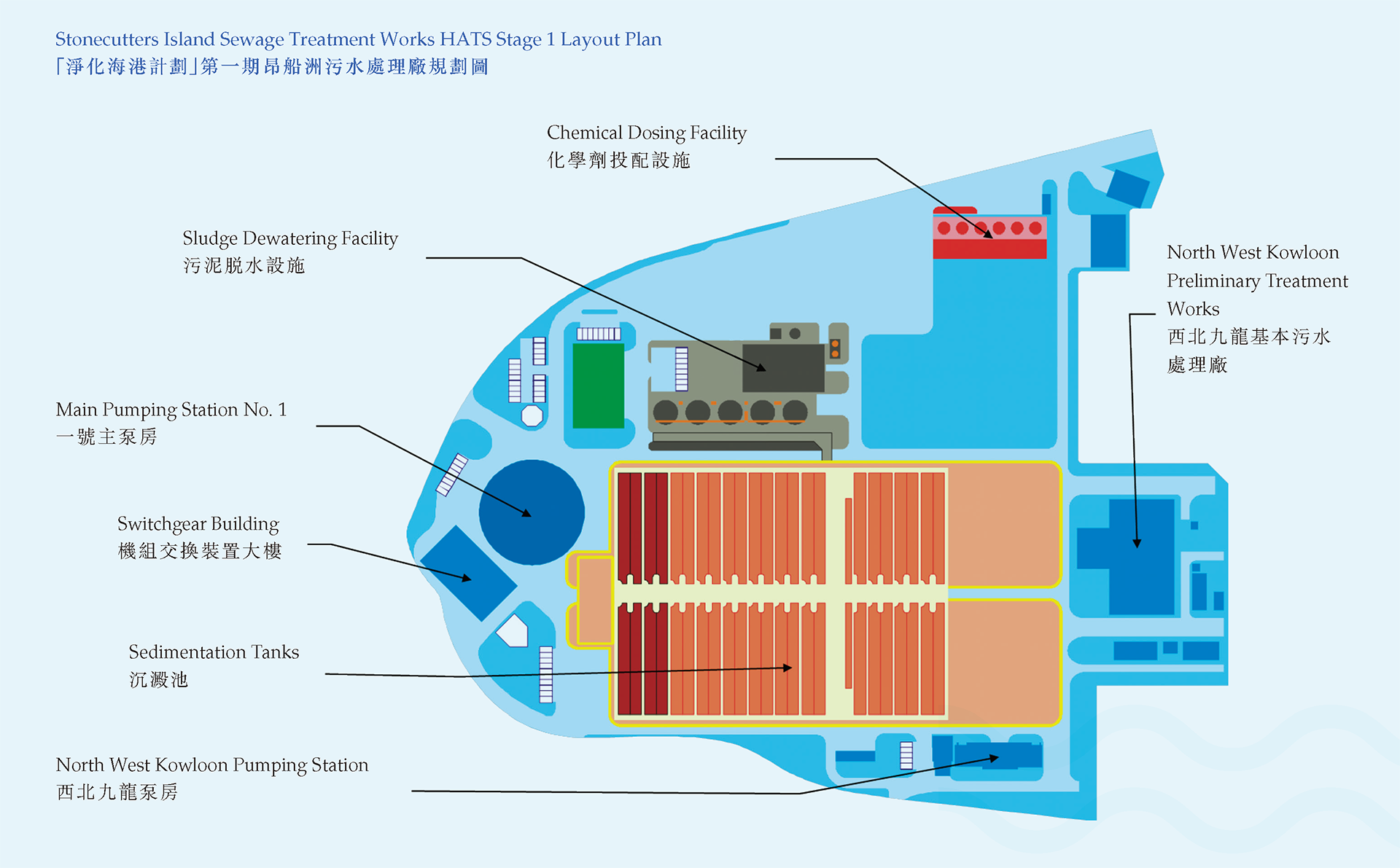

Since 1997, when Hong Kong became a Special Administrative Region of the People’s Republic of China, Stonecutters Island has housed naval facilities as well as a number of civil facilities, including the newly commissioned Stonecutters Island Sewage Treatment Works (SCISTW). Also on the island is the pre-existing North West Kowloon Preliminary Treatment Works (NWKPTW), which serves Sham Shui Po, Yau Ma Tei and Cheung Sha Wan.

Stonecutters Island was chosen to house the centralised sewage treatment works for an obvious reason: its central location in relation to all the Preliminary Treatment Works (PTWs) on both sides of the Victoria Harbour covered by the HATS plan keeps the length of the deep tunnels to a minimum. Although SCISTW was designed to ultimately serve the needs of 5.7 million people, the area designated for the entire treatment works was only 10.6 hectares, just about half the size of Victoria Park. The result is a world-class, compact and highly efficient sewage treatment works.

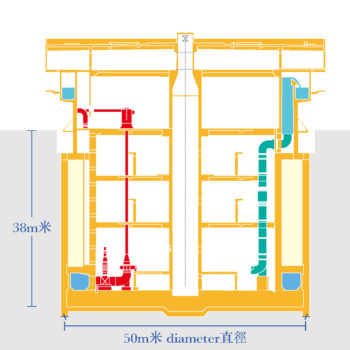

Overview of Main Pumping Station No.1

Stonecutters Island Sewage Treatment Works

The SCISTW is a key component of HATS Stage 1 and provides centralised chemically enhanced primary treatment (CEPT) to preliminarily treated sewage collected from the deep tunnel system. SCISTW is designed to handle average dry weather flow of 1.7 million cubic metres per day. HATS Stage 1 is intended to serve about 3.5 million people, with further HATS stages taking that number up to 5.7 million.

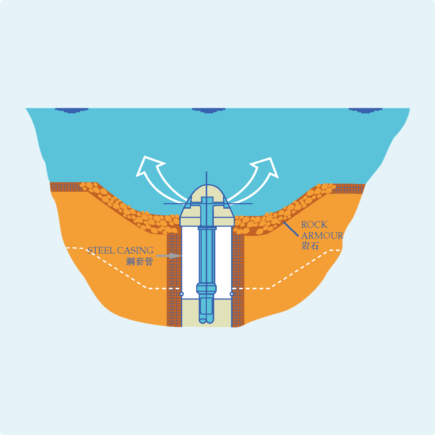

The SCISTW consists of six main facilities, all constructed during HATS Stage 1, including: Main Pumping Station No. 1, Sedimentation Tanks Facility, Chemical Dosing Facility, Sludge Dewatering Facility, Power Supply and Control System, and Stage 1 Outfall System.

Main Pumping Station No. 1

The large Main Pumping Station No. 1 (MPS1) is designed to lift the sewage from the deep tunnel system and deliver it to downstream treatment facilities above ground. For compactness, the MPS1 is circular, with a diameter of 50 metres and a depth of over 38 metres. The wet well is located at the periphery, while the central space houses the pumps, motors and control room. The pumping system comprises eight gigantic centrifugal pumps, together with four variable speed drives for energy efficient operation.

Main Pumping Station No.1 under construction

Sectional View of Main Pumping Station No.1