Dear Harbour,

After the successful commissioning of HATS Stage 1 in December 2001, the Government decided to go ahead with HATS Stage 2 in 2004 after thorough expert reviews, numerous technical studies and extensive public consultation.

Let’s turn the clock back to the early 2000s to get a sense of things at that juncture.

Stage 2A: Treating the Remaining 25% Sewage

Remarkable water quality improvements were seen in the middle and eastern areas of the Harbour upon completion of HATS Stage 1, which provided treatment to 75% of sewage from urban districts on both sides of the Harbour. However, the remaining 25% of sewage, originating from the northern and south-western parts of Hong Kong Island, was yet to be intercepted. Some 450,000 cubic metres of virtually untreated sewage was still being directly discharged into the Harbour each day.

Another complication was that the western harbour was still being affected by the large volume of effluent from the Stonecutters Island Sewage Treatment Works (SCISTW) without disinfection. Further investment in HATS was needed to resolve these issues and make our entire Harbour healthy again.

Stage 2A Works Scope

HATS Stage 2A included these major works:

- Upgrading of eight existing Preliminary Treatment Works (PTWs) at North Point, Wan Chai East, Central, Sandy Bay, Cyberport, Aberdeen, Wah Fu and Ap Lei Chau to enhance their screening and degritting facilities

- Construction of around 21 kilometres of long, deep sewage tunnels to collect and transfer sewage from these eight PTWs to SCISTW for treatment

- Upgrading the existing chemically enhanced primary treatment (CEPT) capacity of SCISTW from the existing design level of 1.7 million cubic metres per day to about 2.45 million cubic metres per day

- Disinfection facilities at SCISTW, given priority ahead of other works, to tackle water pollution at beaches in Tsuen Wan

- A new Distributed Control and Data Acquisition System (DCDAS)

Stage 2A works began in 2009. Works for part of the disinfection facilities were advanced, with early commissioning in 2009 to facilitate the re-opening of seven closed Tsuen Wan beaches in the western harbour.

HATS Stage 2A Tunnels Alignment

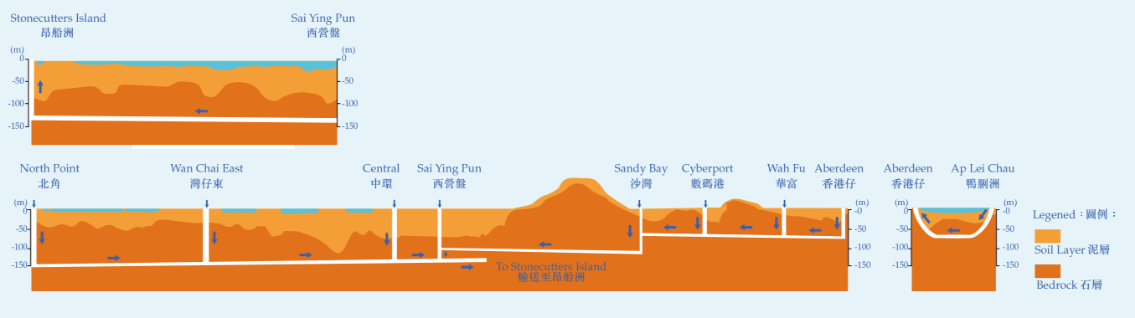

HATS Stage 2A Tunnels Longitudinal Profile

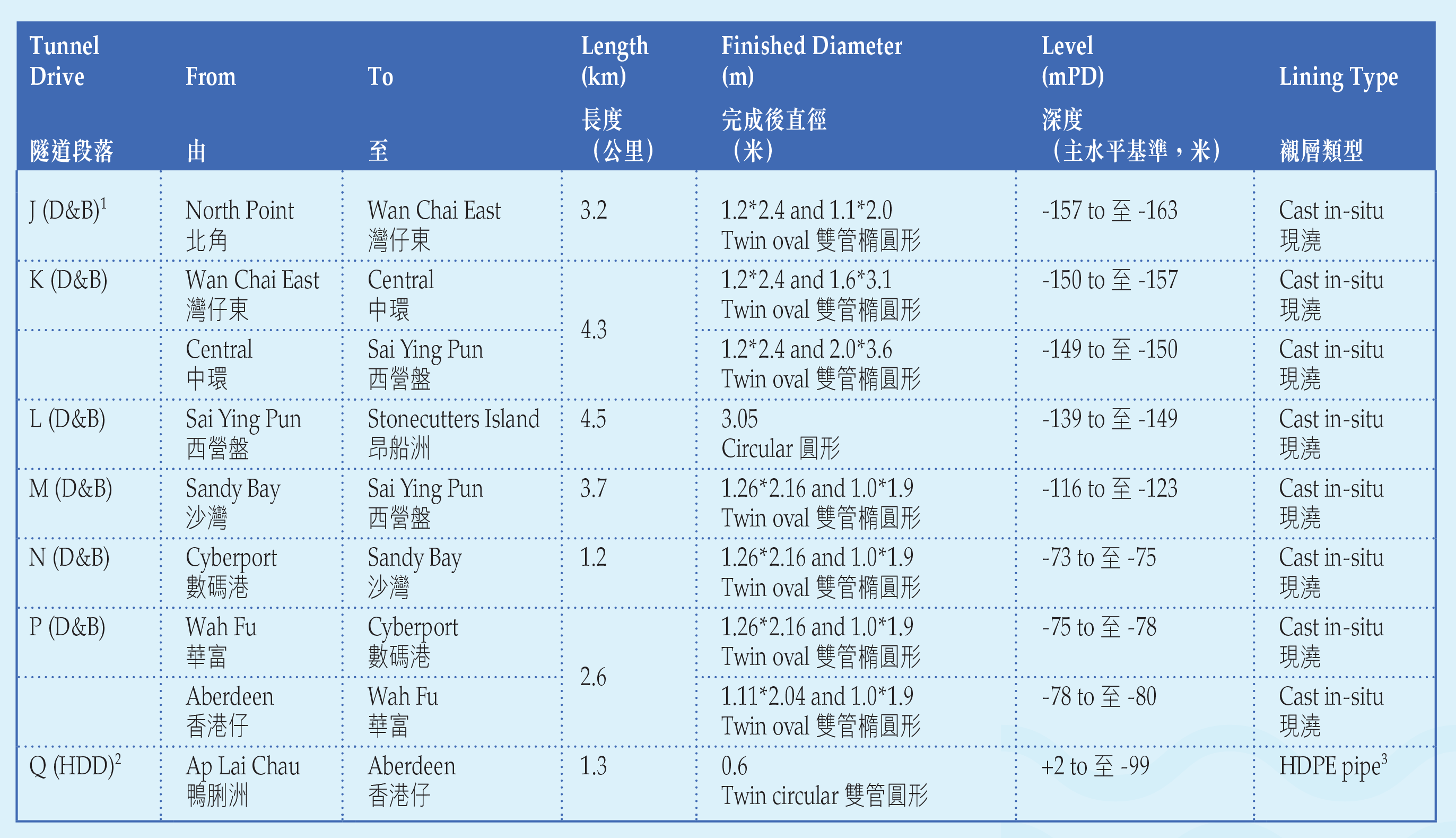

Information of HATS Stage 2A Tunnels

Notes:

1. “D&B” means drill and blast method.

2. “HDD” means horizontal directional drilling method.

3. “HDPE” means high density polyethylene.

Advance Disinfection Facility

The provision of disinfection facilities at Stonecutters Island to prevent pollution in the western part of the Harbour, where effluent was discharged from SCISTW, was urgent and had to be tackled as early as possible.

Accordingly, the Government conducted in 2005 an environmental impact assessment (EIA) study for the Advance Disinfection Facilities (ADF) to be built at SCISTW. The EIA study concluded that chlorination using sodium hypochlorite was the preferred option.

Construction of the ADF commenced in April 2008. By December 2009, the facilities began providing disinfection to Stage 1 effluent from SCISTW prior to its discharge into the Harbour, with immediate positive impacts. When the ADF was put into full operation in March 2010, it significantly improved the water quality of Victoria Harbour, in particular in its western part.

Seven Tsuen Wan beaches were re-opened progressively, with the last one re-opened in 2014. Indeed, the Cross Harbour Race had already resumed in 2011 in the east of the Harbour after years of suspension, thanks to greatly improved water quality.

Upgrading Eight PTWs

Eight existing PTWs in the northern and south-western parts of Hong Kong Island had to be upgraded to cater for the technical requirements of HATS Stage 2A. Works included the installation of 4-millimetre fine screens to trap small objects and degritting facilities to remove 95% of grit greater than 0.2 millimetres, all to avoid clogging of the deep sewage tunnels, as well as the replacement of pumps.

Aesthetics of the PTWs was improved, adding greenery and rooftop photovoltaic panels for renewable energy. Deodourisation units were built too, bringing lasting environmental benefits to nearby residents.

Deep Tunnel System

With geology and design similar to the Stage 1 tunnels, Stage 2A comprises a network of interconnected deep tunnels at a total length of 21 kilometres located at depths varying from 70 metres to 160 metres below sea level.

With experience gained from Stage 1 works, detailed considerations were made at an early stage in the investigation and design of the Stage 2A tunnel system. An innovative and state-of-the-art technology called Horizontal Directional Coring was adopted to investigate the geology, which cored continuously for as far as 1,247 metres from the coring point in one tunnel section to obtain continuous rock cores directly along the tunnel route.

Stage 1 works had proved that pre-excavation grouting was the most practicable and effective means in controlling ground water ingress under great pressure. One of the key difficulties of Stage 1 tunnel works was the modification of the Tunnel Boring Machines (TBMs) to provide them with mechanical equipment for drilling grout holes around the tunnel perimeter in front of the excavation face, because of limited working space.

With this in mind, and making reference to hard rock tunnelling experience elsewhere in the world, particularly in Scandinavian countries, the project team decided that the use of drill and blast method would allow pre-excavation grouting to be carried out in the most effective manner. The contractor was therefore required to procure a tailor-made drilling jumbo with state-of-the-art drilling equipment mountings to facilitate pre-excavation grouting operation and the drilling of blast holes.

Drilling jumbo

Drilled blast holes on a blast face

Government explosives delivery truck

Detonators for explosives

Deep sewage tunnel under construction

Shaft connecting deep sewage tunnel under construction

6,990 blasts were completed in HATS Stage 2A project

Twin oval tunnels

Technical requirements for the blasting operation were carefully assessed and determined at an early stage to allow the operation to be carried out in a safe manner. Detailed arrangements and procedures were discussed and agreed in advance with the relevant authority, the Commissioner of Mines, on the delivery and use of explosives for the blasting works. Adopting the drill and blast method also made it possible for the project team to design a curved tunnel alignment to minimise encroachment into private lots. At the same time, the lower set-up cost of blasting, as compared with the use of TBMs, would allow excavation to be carried out concurrently from both ends of a tunnel section to speed up progress. As it transpired, after commencement in July 2009, all the Stage 2A tunnelling works were completed in June 2015 in a systematic and well controlled manner.

The tunnel from Ap Lei Chau to Aberdeen stood out as one with construction difficulties foreseen at an early stage. The presence of a major geological fault zone, the Aberdeen Fault, would pose serious challenges for tunnelling even if pre-excavation grouting coupled with various kinds of ground supports were used. In order to minimise the risks in tunnelling through this weak ground zone, it was decided to construct this tunnel section with state-of-the-art Horizontal Directional Drilling technology. More on this in the next letter.

Upgrading Works on Stonecutters Island

Key upgrading works at SCISTW included constructing a second main pumping station and additional CEPT tanks, expanding the sludge dewatering facilities, adding new disinfection facilities and deodourisation units, and implementing a new control system for all these additional facilities. Let’s begin with the new pumping station.

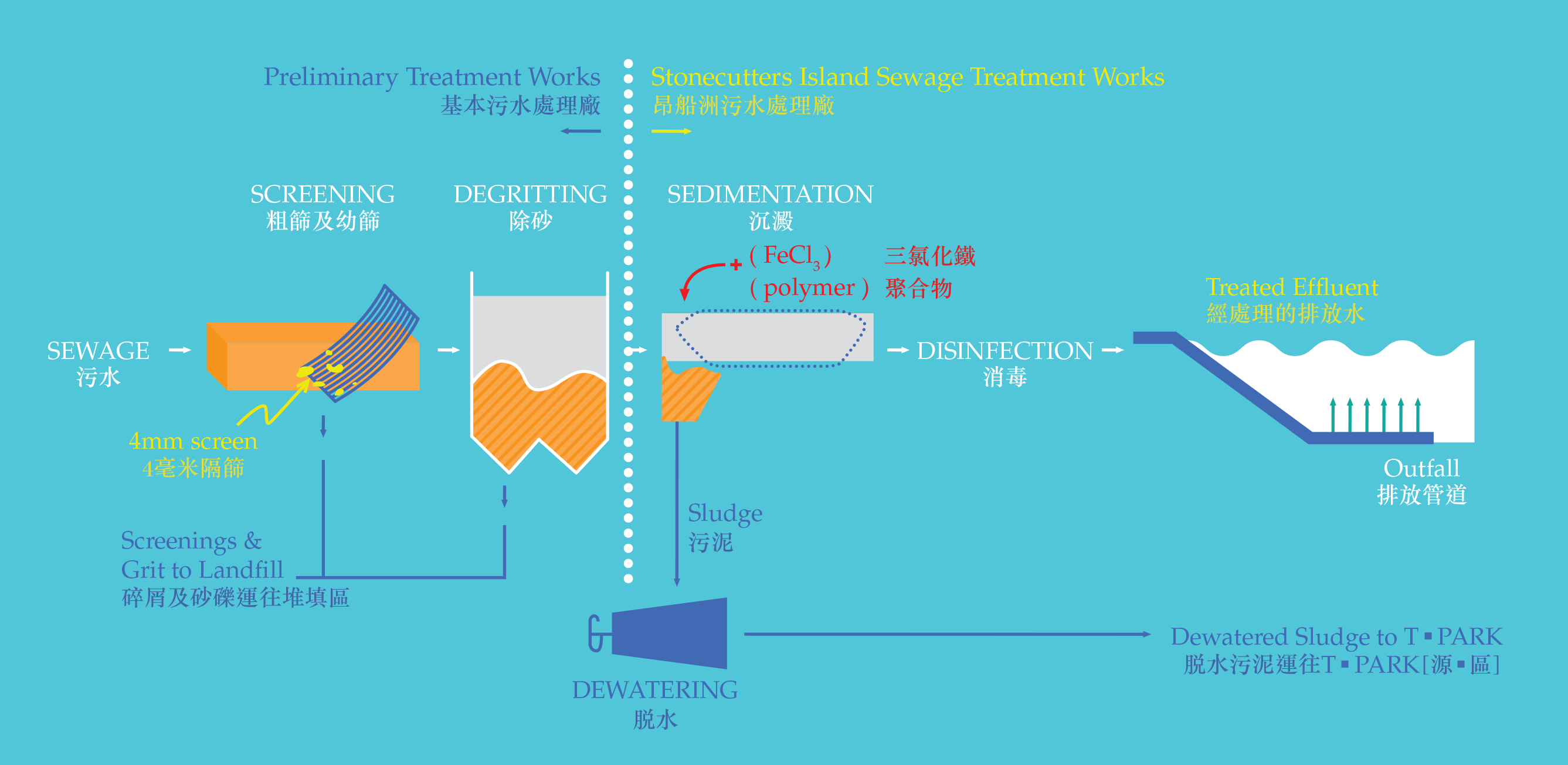

HATS Sewage Treatment Process

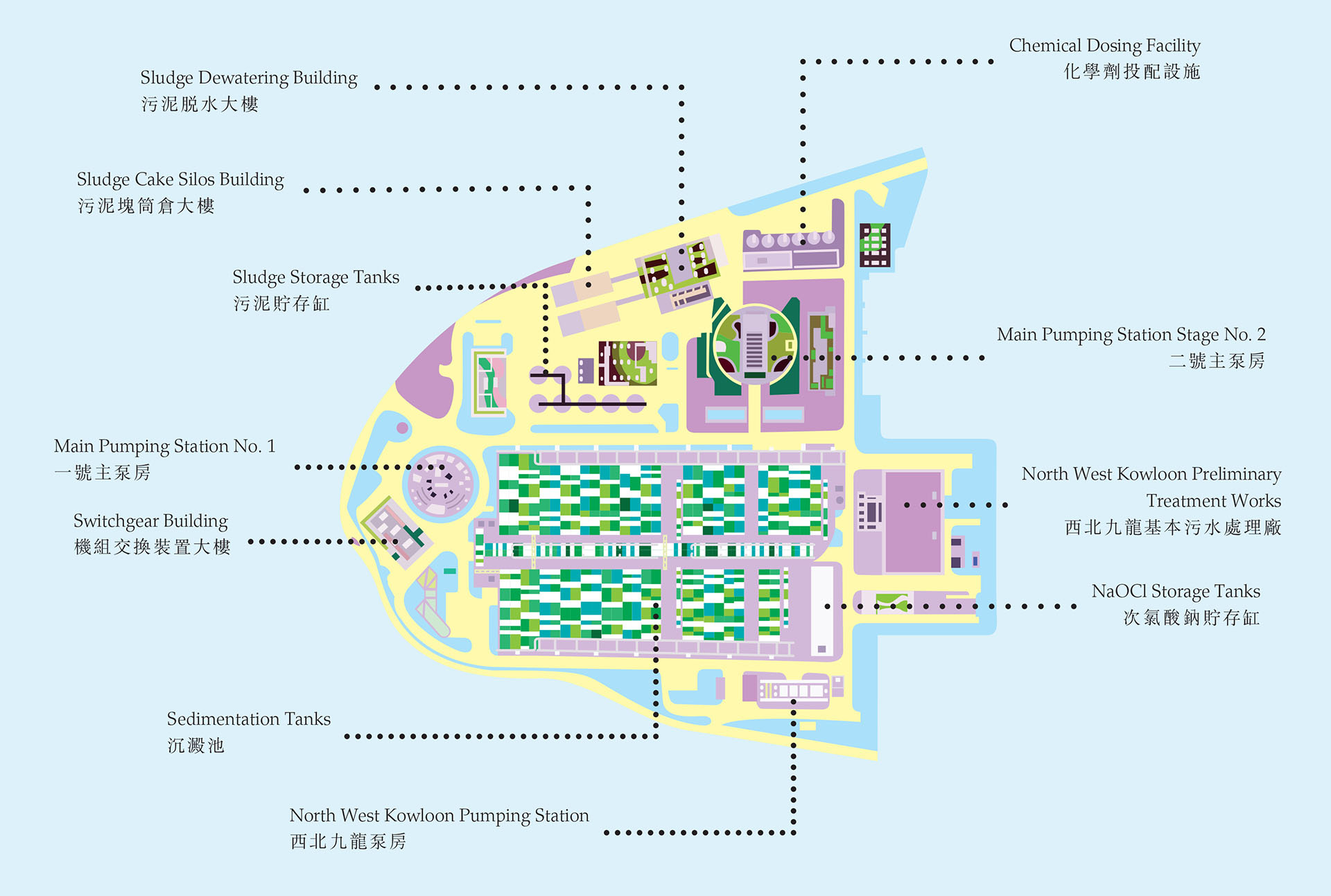

Stonecutters Island Sewage Treatment Works HATS Stage 2A Layout Plan

Main Pumping Station No. 2

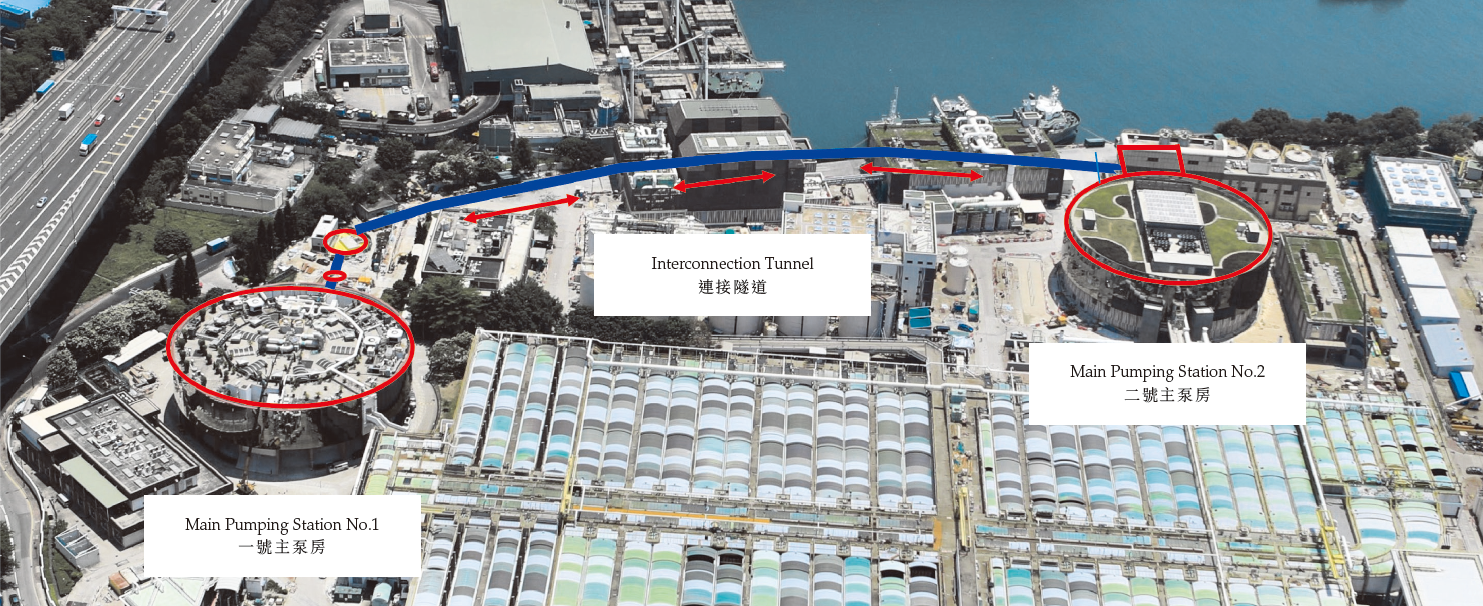

The Main Pumping Station No. 2 (MPS2), comprising eight pumps, is designed to cater not only to lift additional sewage flows from Stage 2A deep tunnels to the surface for treatment, but also to provide flexibility for sewage flow that may be diverted from MPS1, the Stage 1 pumping station, in case of machinery breakdown or major overhauls.

The maximum pumping capacity of MPS2 is 32 cubic metres per second, augmenting the MSP1 maximum pumping capacity of 31.2 cubic metres per second. MPS2 comes with two wet wells to allow flexibility in operation and ease of future maintenance. An underground interconnection tunnel of 250 metres long was built between MPS2 and MPS1, again for operational flexibility and future maintenance.

Motor hall of Main Pumping Station No. 2

Overview of Main Pumping Station No. 2

Sewage pump of Main Pumping Station No. 2

Tunnel boring machine used for interconnection tunnel construction

Interior structure of interconnection tunnel

Underground interconnectional tunnel connecting between MPS1 and MPS2

Sedimentation Tanks

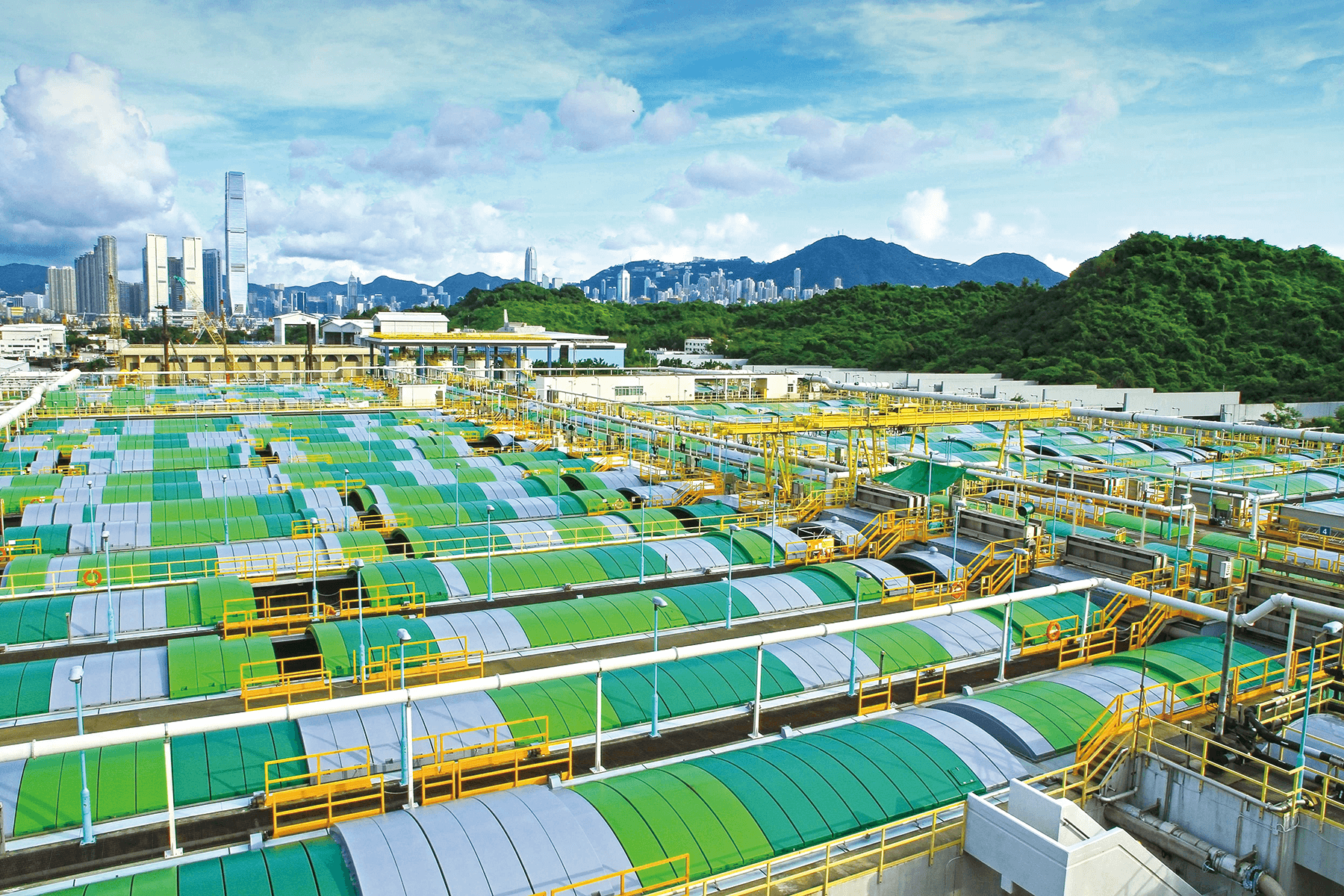

Also at the core of the SCISTW upgrading works was the construction of eight additional double-deck sedimentation tanks, bringing the total number of sedimentation tanks to 46.

An advance contract was let to provide deodourisation facilities and to supply fibre-glass covers in three vivid colours for all the existing Stage 1 CEPT tanks, for completion in 2012. These measures have alleviated to a large extent the odour nuisance to nearby residents in Sham Shui Po, Cheung Sha Wan and West Kowloon.

Double-decked sedimentation tanks with fibre-glass covers

Disinfection Facility

One of the main reasons for implementing HATS Stage 2A was to address the need to disinfect CEPT-treated sewage to avoid polluting the Harbour.

After the CEPT process, sodium hypochlorite, or bleach, is added to the effluent for disinfection. Effluent from both Stages 1 and 2A undergoes disinfection in a new effluent tunnel which also functions as the chlorine contact chamber. The bleach kills more than 99% of E. coli, a step vital to restoring water quality in our Harbour. Prior to discharge, the effluent then also undergoes a de-chlorination process to neutralise the residual chlorine for protection of the marine ecosystem.

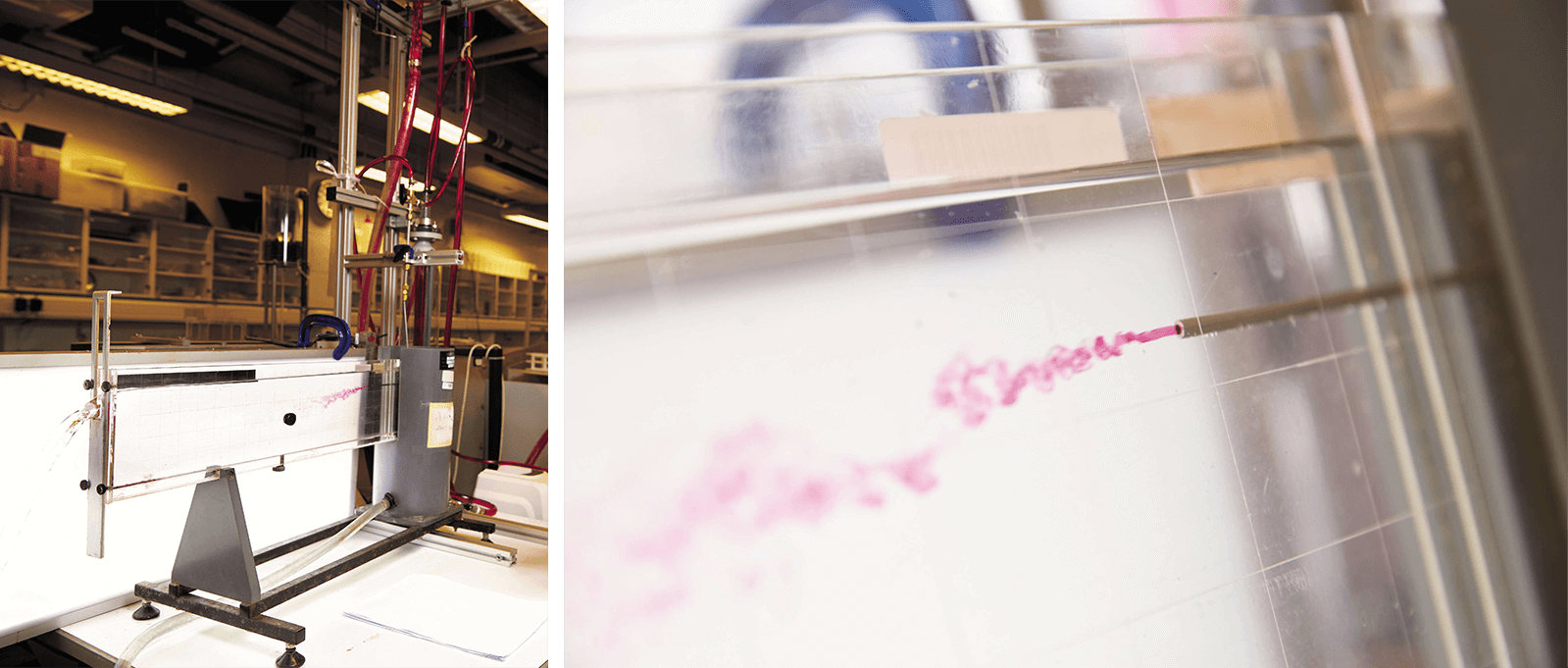

Computational Fluid Dynamic (CFD) modelling in conjunction with physical models were used to enhance the disinfection process, such as testing the effectiveness of different concentrations of sodium hypochlorite and dosing locations. As a result, a second dosing unit was added just before the overflow weir to the drop shaft to optimise mixing of chemicals with sewage.

Meanwhile, another valuable tool called Waterman was developed by Professor Joseph LEE, a renowned expert in environmental hydraulics. An advanced modelling tool, Waterman helps predict the far field effect of effluent discharged from outfall diffusers, and shows how the effluent impacts the water quality at nearby beaches under different weather and tidal conditions.

These modelling tools proved very useful in understanding the impacts and minimising the consumption of chemicals for optimal disinfection.

Hydraulic model for optimisation of disinfection facilities in SCISTW

Sludge Dewatering Facility

A new sludge dewatering building housing 14 gigantic centrifuges was built to cater for sludge generated from HATS Stages 1 and 2A. The sludge dewatering capacity was increased from 600 tonnes per day to 1,200 tonnes per day.

A solid pumping system is used to convey dewatered sludge to a total of 16 sludge cake silos, designed to provide ample storage in case of adverse weather conditions delaying the transportation of dewatered sludge. Indeed, two ocean-going vessels for transporting sludge to T · PARK in Tuen Mun for incineration were built, too. More on that sustainability story later.

Sludge dewatering building

Sludge cake silos buildings

Centrifuges inside the sludge dewatering building

Deodourisation Units

Deodourisation units (DOUs) were added to various potentially odorous facilities at SCISTW, including pumping stations, sludge dewatering buildings, sludge cake silos and sedimentation tanks, all of which are enclosed to ensure the odour stays inside. Odorous gas is ducted to DOUs using bio-trickling filters, wet chemical scrubbers or activated carbon units for treatment before discharge.

Deodourisation units

New Control System

A new Distributed Control and Data Acquisition System (DCDAS) was added to allow for the integrated control of the whole HATS system. An expert system was developed to assist in training SCISTW operators, using different operational simulations and providing an advanced decision support system.

Stage 2A Commissioned in 2015

After six years of hard work, HATS Stage 2A was commissioned in December 2015. From then onwards, all sewage from urban Kowloon and Hong Kong on both sides of the Harbour would be fully treated at one of the world’s best CEPT sewage treatment works. We would have no more beach closures nor coral decay because of harbour pollution.

Swimming Again!

The commissioning of Stage 2A brought further improvements to our marine water quality, so much so that the Cross Harbour Race, the annual swimming gala first held in 1906 but suspended from 1978 to 2010 due to rising pollution in the Harbour, was moved back to the central part of the Harbour in 2017. This was further to the resumption of the Race in 2011 in the eastern part of the Harbour when the water quality was already suitable for swimming.

So, dear Harbour, this is the story of HATS, so far as major construction work goes. The HATS vision has come true, and Victoria Harbour is fragrant and healthy again.

POSTSCRIPT

“For the past 20 years I have focused on buoyant jet diffusion study, which aims to make effluent dilute within a short period of time and a small area so as to protect the environment. I also developed a mobile application called Waterman which utilises big data to make real-time analysis of water quality in all of Hong Kong’s beaches. This is particularly useful to protecting the beaches in Tsuen Wan, and can help us give alerts and take contingency measures when emergencies arise.”

“Universities conduct basic research, but practical problems are highly complex. Our long-term cooperation with the Drainage Services Department is complementary. It helps us give back to the community and is valuable to our teaching and grooming of talent. HATS is among the world’s top engineering projects. I am honoured to be part of it.”

Professor Joseph LEE Hun-wei

Professor Emeritus and Visiting Professor of Department of Civil & Environmental Engineering,

Senior Advisor to the President and Chair Professor of Guangzhou Fok Ying Tung Research Institute at the Hong Kong University of Science and Technology