Sewage Collection, Treatment and Disposal

Latest development of Harbour Area Treatment Scheme Stage 2A

Overview

The Harbour Area Treatment Scheme (HATS), consists of two stages, aims to improve the water quality of Victoria Harbour by intercepting and treating sewage generated from both sides of the Harbour. HATS Stage 1 was commissioned in December 2001 and Stage 2A, now in progress, is targeted for completion in end 2014.

The HATS Stage 2A comprises three parts, namely, upgrading works for the Stonecutters Island Sewage Treatment Works (SCISTW), upgrading works for eight preliminary treatment works and construction of the sewage conveyance system. During the year, the works under the awarded contracts are progressing smoothly.

Part 1: Upgrading Works for Stonecutters Island Sewage Treatment Works

In July 2012, the construction of interconnection tunnel and diaphragm wall for the new main pumping station were successfully completed with the gratifying result of zero site accident. The tunnel of 3.9 metres in diameter, 236 metres long and 30 metres deep, was excavated and lined by "Victoria", an earth-balanced tunnel boring machine. Such completion enables the integrated use of the existing main pumping station and the new main pumping station, and will in turn enhance the reliability of the whole sewage treatment system.

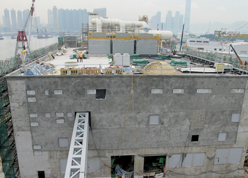

Another major upgrading works at SCISTW include the construction of a new main pumping station, with an internal diameter of about 55 metres and a depth of about 40 metres. The circular-shaped new main pumping station will be able to house eight sets of new pumps with capacity of four cubic metres per second each. The additional flow can fill up a Olympic-size swimming pool in 10 minutes. The combined design capacity of the eight pumps can boost the daily sewage handling capacity from the current 1.7 million cubic metres to 2.45 million cubic metres. The upgrading works are now in full swing and it is anticipated to be commissioned in 2015.

The two deodorisation units and covers for the sedimentation tanks were completed in June 2012, and testing and commissioning was completed successfully in September 2012

Part 2: Upgrading Works for Eight Preliminary Treatment Works

This includes the upgrading of the eight preliminary treatment works (PTW) around the northern and southwestern shore of Hong Kong Island at North Point, Wan Chai East, Central, Sandy Bay, Cyberport, Wah Fu, Aberdeen and Ap Lei Chau. All works under the awarded contracts are progressing satisfactorily.

Construction of fine screen and grit trap building at North Point and Central PTW is in progress with commissioning tentatively scheduled in mid 2013

Part 3: Construction of the Sewage Conveyance System

The 21 kilometre-long sewage conveyance tunnel, with depth of maximum 160 metres below sea level, is one of the deepest sewage tunnel in the world.

During the year, there has been ongoing deep tunnel excavation adopting drill-and-blast method at North Point, Wan Chai East, Sandy Bay, Cyberport, Aberdeen, Sai Ying Pun and Stonecutters Island sites. Excavation of the vertical shaft also continues at the Wah Fu site.

Excavation has been completed for the 910 metre-long tunnel from Stonecutters Island to Sai Ying Pun, 870 metre-long main tunnel from Wan Chai East to Sai Ying Pun and 1,900 metre-long tunnel from Wan Chai East to North Point.

Odour Containment System at Stonecutters Island Sewage Treatment Works Completed

The installation of covers for the sedimentation tanks and construction of two deodorisation units at SCISTW were completed in June 2012 and testing and commissioning was completed satisfactorily in September 2012. This assures a better air quality to the surrounding environment.

The state-of-the-art odour containment system, comprising fiberglass reinforced plastic covers with total area of 25,000 square metres, covers all the 46 sedimentation and flocculation tanks and related facilities. The system also consists of an air extraction ductwork with an extraction rate of 112,000 cubic metres per hour, as well as two deodorisation units adopting biotrickling filter technology with hydrogen sulphide (H2S) removal efficiency up to 99 per cent.

After the completion of the fiberglass reinforced plastic covers installation, we invited the local residents to inspect our odour management measures. Site visits were organised for Sham Shui Po District Council and residents from Mei Foo on 12 October 2012 and 24 November 2012 respectively.