Our Core Responsibilities

Overview of Sewage Treatment and Sewerage System 2016-17

Sewage collection, treatment and discharge is one of DSD's core services. Through application of different of sewage treatment processes and advanced technologies, most of the pollutants, toxins and bacteria are removed from sewage to meet the respective discharge standards and legal requirements.

At present, we operate 304 sewage treatment facilities and treat about 2.8 million cubic metres of sewage on average every day.

Location map of Sewage Treatment Works (STW) in 2016-17

Summary of Sewage Treatment Facilities and Sewerage Network 2016-17

- 1,015

Annual sewage treatment volume (million m3) - 93.5%

Coverage of public sewerage (Population percentage)

Based on the no. of domestic water bill accounts with sewage charges levied - 1,755

Total length of sewerage network (km) - 304

Total no. of sewage treatment facilities

In 2016-17, we treated a total of about 1,015 million cubic metres of sewage, of which 4.4% received preliminary treatment, 76.7% chemically enhanced primary treatment (CEPT), 18.4% secondary treatment, and the remaining 0.5% primary & tertiary treatment.

Sludge is produced during the sewage treatment process. 410,526 tonnes of sludge were collected and treated in 2016-17.

Proper maintenance is always carried out to ensure that the sewage collection, treatment and disposal facilities operate effectively. In support of Hong Kong's sustainable development, we will continue to expand the coverage of the sewage collection network and improve the treatment facilities continuously.

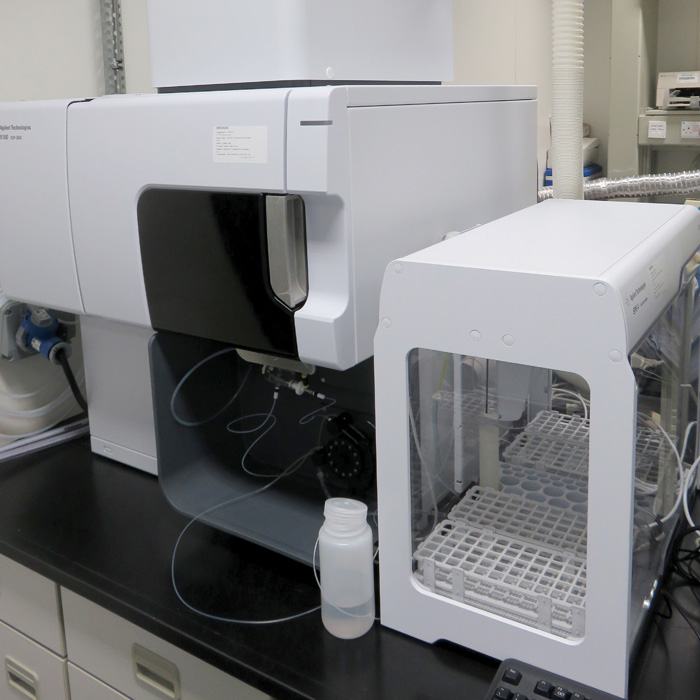

Professional Laboratory Services

DSD operates a number of laboratories to provide professional laboratory services to ensure that treated sewage meets the statutory requirements. Since 1999, our Shatin Central Laboratory and Stonecutters Island Laboratory have been accredited for testing of environmental samples (water & wastewater) under the Hong Kong Laboratory Accreditation Scheme (HOKLAS) operated by the Hong Kong Accreditation Service of the Innovation and Technology Commission. The Stonecutters Island Laboratory has also gained accreditation since 2007 for testing of chemical samples to assure that the procured chemicals for sewage treatment conform with the contract specifications. A new inductively coupled plasma-optical emission spectrometer was purchased in December 2016 and commissioned in early 2017 at the Shatin Central Laboratory, which can further enhance the performance on detecting heavy metals in sewage and sludge samples. During the year, 31 of our laboratory tests were accredited.

Analytical Services

To improve precision of instruments and monitor water quality and efficiency of the sewage treatment process, we carry out sewage sampling and analysis regularly. These measures can ensure that treated sewage meets specified discharge requirements and accurate water quality data are provided.

Extensive laboratory testing covering more than 14 types of analysis of sewage samples is carried out in our laboratories in Shatin, Tai Po, Sai Kung, Shek Wu Hui and Yuen Long. In 2016-17, these laboratories conducted over 266,600 analyses in total. The analytical results of effluent quality of major sewage treatment works can be found on our website.

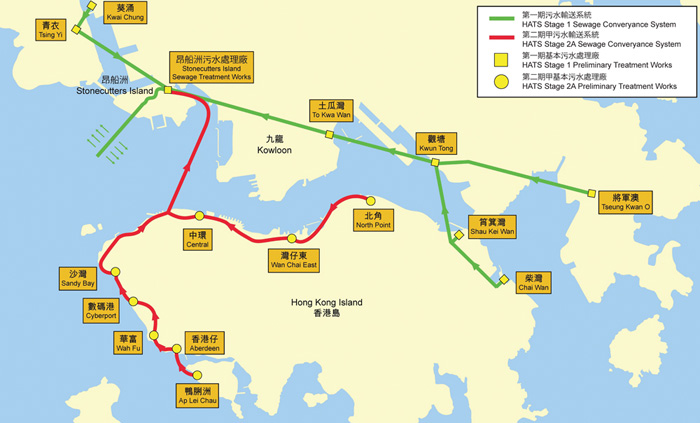

Harbour Area Treatment Scheme (HATS)

Following its full commissioning in December 2015, the HATS Stage 2A project completed another milestone this year. After months of preparation and planning, two 3-metre-diameter concrete plugs located at -24mPD in the HATS Stage 1 riser shaft were successfully removed in January 2017, connecting the two main pumping stations in the Stonecutters Island Sewage Treatment Works (SCISTW) by the interconnection tunnel. Testing and commissioning of the interconnectional tunnel were completed on 24 March 2017. This allows sewage to be handled by either of the two main pumping stations in the dry season, which greatly enhances the operation flexibility and reliability of the SCISTW.

Current progress

Construction of the remaining facilities of HATS Stage 2A, including the southern sludge cake silo and the workshop buildings, is now in full swing. Beautification works such as green roofs, landscaping and architectural features, are also in progress. Completion of these works in the near future will serve to enhance our sewage treatment services to the public.

Stakeholder Interview

Contractor's Note

We are commissioned by DSD to design, construct and operate the sludge cake handling facilities for the Stonecutters Island Sewage Treatment Works under HATS Stage 2A. After designing and building two container vessels for sludge transportation ― “Clean Harbour 1” and “Clean Harbour 2”, we carry out routine duties to transfer dewatered sludge cakes using purpose-built containers and the Clean Harbour vessels from Stonecutters Island Sewage Treatment Works to T‧Park in Nim Wan, Tuen Mun, for further treatment. the Clean Harbour vessels are the first diesel-electric propulsion container vessels in Hong Kong, using ultra-low sulphur diesel to generate electricity for propulsion; and they are connected to on-shore power supplies when berthed, without using diesel and thereby achieving zero emission.

DSD has allocated considerable resources to continuously improve the sludge dewatering process in support of Hong Kong's sustainable development. In addition to inspecting, maintaining and renewing equipment on a regular basis, DSD keeps a close eye on the overall quality of the sludge treatment process. DSD will follow up and take immediate action if there is change in sludge quality to address unusual circumstances.

We work closely with DSD in our daily operation. Given that the sludge dewatering process may be affected by equipment maintenance and change in weather, we keep close contact with the sewage treatment plant to ensure that adequate manpower and vehicles can be deployed in case of emergency situations to ensure the provision of stable and reliable services for the public. As a working partner of DSD, we will continue to support the department's initiatives.

DSD's Note

DSD is grateful to stakeholders’ for their recognition and support of our sustainability efforts. Bolstered by valuable and pragmatic feedback from the industry, we are dedicated to applying more new technologies to our operation. Such communication can also enable us to develop a close rapport with the industry. We will continue to work closely with the industry to optimise DSD's operation efficiency and service quality and foster the long-term sustainable development of Hong Kong.

Planning, Design and Construction of New Sewerage Facilities

Construction of additional sewage rising main and rehabilitation of the existing sewage rising main between Tung Chung and Siu Ho Wan

To enhance the overall operation and reliability of the sewerage system for Tung Chung Town and Airport Island, and to cope with the increased sewage flow from the development of the Tung Chung New Town Extension, we will construct an additional sewage rising main of about 6.5 kilometres with diameter of 1,200 millimetres from the Tung Chung Sewage Pumping Station to the Siu Ho Wan STW. The existing sewage rising main will also be rehabilitated.

Current progress

Construction of the new sewage rising main commenced in August 2016 and is scheduled for completion in July 2022. Upon completion and operation of the new sewage rising main, the existing main can be temporarily decommissioned for rehabilitation. The rehabilitation works are expected to be completed in late 2025.

Upgrading of San Wai STW - Phase 1

The existing San Wai STW is a preliminary sewage treatment works with treatment capacity of 164,100 cubic metres per day. The Upgrading of San Wai Sewage Treatment Works - Phase 1 project will increase the capacity to 200,000 cubic metres per day and raise the treatment level to chemically enhanced primary treatment with ultraviolet disinfection. The upgrading works will help raise the water quality of to the north-western waters and cope with growing population in the area.

Current progress

This project was procured through a Design-Build-Operate (DBO) contract, which commenced in May 2016 and is scheduled for completion in 2020. Upon completion of construction works, the contractor will undertake the operation and maintenance of the new San Wai STW for a period of up to 15-years.

Expansion of Shek Wu Hui STW

In line with the rapid development of North District, we will expand the treatment capacity of Shek Wu Hui STW in phases and upgrade it to a tertiary treatment plant to better protect the ecological environment of Deep Bay. We will also take this opportunity to revamp its exterior and environmental performance, and promote its educational purpose on water conservation so as to transform Shek Wu Hui STW into an iconic, multipurpose community facility.

Current progress

This project is executed in stages. Advance works commenced in July 2015 and are expected to complete in 2019. Detailed design of the main works employs the innovative building information model (BIM). We will strive for the earliest completion of the advance works and commence the extension works for subsequent stages.

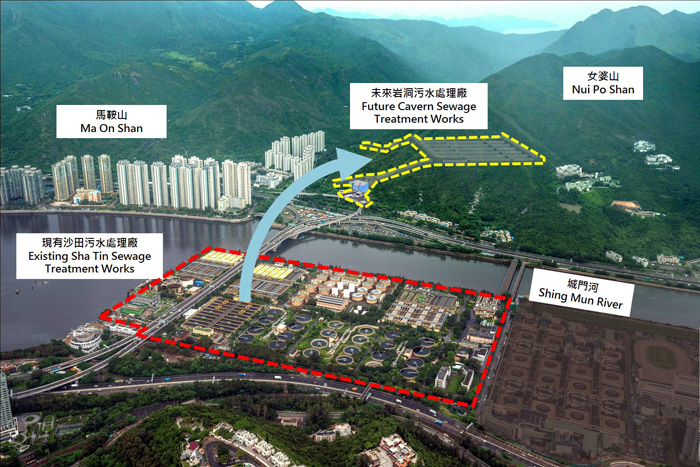

Relocation of Sha Tin STW to Caverns

In addition to releasing some 28 hectares of land for other beneficial uses, the relocation of the Sha Tin STW to caverns can improve the living environment of the district.

Current progress

Site investigations and enhancement of the detailed design on sewage treatment are well under way. The environmental impact assessment (EIA) has been approved by the Director of Environmental Protection whereas the third stage of our public engagement exercise commenced in December 2015 were concluded in May 2016. We will continue to maintain close communication with the local community and stakeholders and strive to optimise the project.

More other, we are also studying the possibility of relocating Sai Kung STW and Sham Tseng STW.

Tolo Harbour Sewerage of Unsewered Areas

We are carrying out sewerage works in Shatin and Tai Po to improve both the water quality in Tolo Harbour and sanitation conditions for 11 unsewered communities. The project involves building a sewage pumping station at Kau To, Shatin and laying about 12 kilometres of sewers for nine and two unsewered areas in Shatin and Tai Po respectively.

Current progress

Construction works commenced in 2013 and are scheduled for completion in November 2018.

Upgrading of Mui Wo STW

In view of future development, we are undertaking improvement works at the Mui Wo STW to boost its daily treatment capacity from 1,190 cubic metres to 3,700 cubic metres. The project will also upgrade the sludge treatment and deodorisation facilities alongside associated greening works.

Expansion of Village Sewerage

DSD has made ongoing efforts to expand the public sewerage systems in villages over the years, in a bid to improve the hygienic conditions in rural areas as well as the water quality of nearby water bodies. Construction works for village sewerage projects are currently underway in North District, Tai Po, Shatin, Yuen Long, Tuen Mun, Sai Kung and outlying islands.

Current progress

As at March 2017, we have laid public sewerage for over 220 villages. Works for other 40-plus villages are in progress and the schemes for more than 230 villages are under planning and design.

Overview of Sewage Services Charges

In accordance with the “Polluter Pays” principle, the Sewage Services Charging Scheme came into effect on 1 April 1995 for all users whose premises are connected to public sewerage. The charge is composed of Sewage Charge (SC) and Trade Effluent Surcharge (TES). There are currently 27 trades under the TES.

Customer Inquiry

DSD's services, whether in relation to sewage treatment or stormwater drainage, are closely related to the daily life of the public. In order to provide better services, we consistently enhance the performance of our facilities and offer a range of routine services to cater for the public’s needs. In 2016-17, we received 6,209 written and telephone inquiries about our sewage services and 99% of the written inquiries were replied within a month.

Written Inquiries Received in 2016-17 by Category

Billing and Water Consumption Statistics

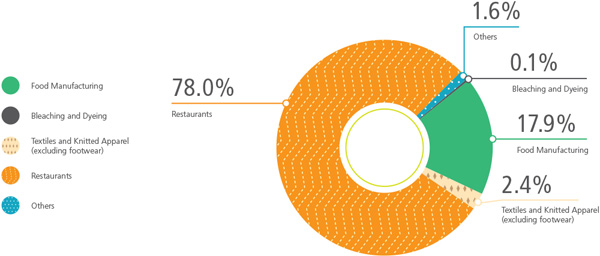

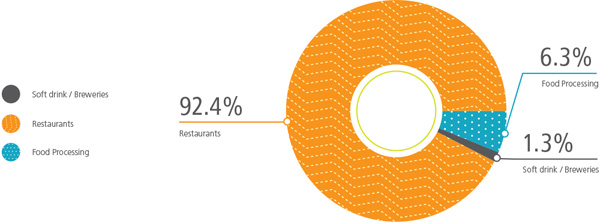

Among some 2.96 million water utility users in Hong Kong, about 2.74 million are required to pay the SC. Among the non-domestic users, about 27,000 are operating in one of the 27 trades required to pay the TES, the distribution of which is as follows:

Distribution of TES Accounts in 2016-17 by Sector

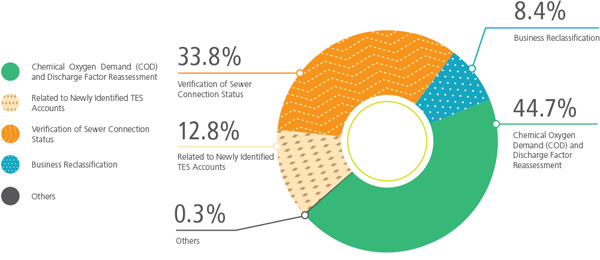

Reassessment of TES Rate and Discharge Ratio

Non-domestic consumers may apply for a reassessment of the TES rate or discharge factor if they consider that their effluent strength or discharge factor is lower than the corresponding values specified by law. The reassessed TES rate is valid for three years.

Managing Underground Drainage and Sewerage Networks

DSD currently manages more than 4,100 kilometres of underground drains and sewers. These underground pipes have been put in service for 29 years on average and over 1,800 kilometres of these pipes have been used for 30 years or more, many of them show signs of wear and tear. We schedule regular inspection plans to monitor the conditions of these underground pipes and conduct rehabilitation works as and when necessary. In 2016-17, we rehabilitated about 22 kilometres of drains and sewers at a cost of about $138 million.

Structural failure of seriously deteriorated pipes may result in road subsidence. Apart from the impact on the operation of the pipelines, it may bring about adverse impacts on traffic, environment and public safety. In view of this, we are striving to implement a territory-wide rehabilitation programme for aged stormwater drains and sewers using risk-based approach. Condition survey and rehabilitation of high risk underground pipes are being implemented in phases. At the same time, we will study and apply various cutting-edge R&R techniques to efficiently maintain our underground pipe networks and achieve greater cost-effectiveness of our works.