|

| Home | The Director's Statement | Our Vision, Mission and Values | Highlights of the Year |

|

| Overview | Ready for the Rainy Days | Let's Clean Up Our Water | Environmental Performance | Let's Contribute |

| New Works

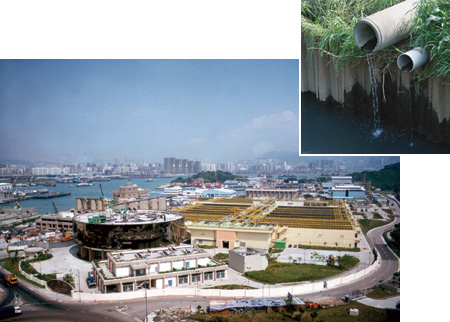

DSD is responsible for the design, construction and commissioning of the sewerage improvement works. This is a huge and hard undertaking because the provision of new and adequate sewerage infrastructure to cope with the rapid development of Hong Kong requires vast resources and the new facilities take time to build. In December 2001, the successful completion of the HATS Stage 1 marks an important milestone in sewage treatment in Hong Kong, as well as a remarkable engineering achievement by international standards. The scheme is now treating over 1.3 million cubic metres of sewage collected from Kowloon and the northeastern part of Hong Kong Island each day, bringing substantial improvement to the water quality of Victoria Harbour. A programme of trials and studies is also being implemented by Government with a view to formulating the way forward for the further stages of HATS. SMP works, which started in 1989, are progressing well. Two SMPs, namely the Chai Wan & Shau Kei Wan SMP and the HK Island South SMP were completed in 1997 and 2000 respectively. The East Kowloon SMP, which involves the construction of about 17 km of sewers and the rectification of expedient connections in the industrial areas in San Po Kong, Kowloon Bay and Kwun Tong, was substantially completed in 2001. The North West Kowloon SMP and Aberdeen, Ap Lei Chau and Pokfulam SMP are making good progress and are now 90% and 80% completed respectively. For Central, Western & Wan Chai West SMP and Wan Chai East & North Point SMP, which serve northern Hong Kong Island, construction for the stage 2 works has commenced. The other SMPs are under various stages of design or construction, and are scheduled for completion in phases by 2013.

Upgrading of major STWs will continue so as to keep pace with increased development and to suit the latest water quality objectives. The upgrading works at Shek Wu Hui STW was substantially completed in August 2001. This financial year we also started the construction works for three major STWs, which include Shatin STW stage 3 extension, Sham Tseng STW and the upgrading of Siu Ho Wan STW. The planning and design for the upgrading of other STWs such as Tai Po STW Stage V, San Wai STW, Pillar Point STW and Sai Kung STW phase 2 is well underway. However, in view of the latest population growth and housing demands, more sewerage facilities and services would be required and reviews of the SMPs are being undertaken by the Environmental Protection Department (EPD). Brief descriptions of major sewerage projects are attached in Appendix D. From the establishment of DSD in 1989 to now, we have been implementing sewerage projects with a total cost of about $31.8 billion, comprising $8.2 billion for HATS Stage I, $17.2 billion for SMP works and $6.4 billion for other associated works. So far, we have completed works amounting to $19 billion under the programme, another $6 billion of works is being planned for the next five years. In 2001/02, the expenditure on sewerage projects was $1.8 billion. |

|

|

Operations and Maintenance of the Sewerage System About 95% of the population is at present served by the public sewerage system with over 98% of the sewage produced being collected and treated. This system includes a sewerage network of about 1,400 km in length. To maintain this extensive and comprehensive network of sewers and to ensure their proper functioning at all times, DSD has implemented a preventive maintenance programme for carrying out regular inspection and cleansing of sewers. In 2001, we have inspected 876 km of sewers, of which 697 km were cleansed, and removed 5,200 m3 of silt, costing a total of about $57 million. To enhance the management of drainage and sewerage assets and the services to the public, DSD completed digitization of all drainage records in 1996. This has enabled us to handle requests for drainage records efficiently. The system is being further enhanced so as to assist the planning of maintenance works and generate statistical reports on assets for better management of resources. In 1997, we installed a Drainage Complaints Information System (DCIS) to replace the manual procedures for recording drainage complaints. All complaints received are directly input into the database so that progress on the follow-up actions can be monitored effectively. This system also serves to identify black spots for planning and reviewing of the preventive maintenance programme. With a view to enhancing the operational efficiency in handling drainage complaints, a Direct Labour Force Mobile Computing Application (DLFMCA) has recently been developed. With the integration of the DLFMCA and the DCIS, the workforce can make use of a Personal Digital Assistant (PDA) to receive work orders, capture work results, take site photos and make sketches on-the-spot. All captured data can be uploaded to the DCIS by a simple operation when the staff return to the depot thus greatly improving the efficiency in processing drainage complaints and facilitating the monitoring of work progress. Following the successful pilot implementation launched in August 2001, the application was migrated to full production in May 2002 to bring full benefits to the operation in handling drainage complaints. Numbers of complaints on blockage of sewers received and dealt with in past years are shown in Appendix E. As the Drainage authority, DSD is responsible for vetting public and private developments with respect to their impacts on the sewerage system. We also provide advice, as necessary, on their connections to the public sewerage system. In 2001, we have processed over 29,000 sets of sewerage-related submissions and issued 154 demand notes for connections for new developments.

|

|

|

Operations and Maintenance of Sewage Treatment Facilities DSD is currently operating about 200 sewage handling facilities including about 60 STWs scattered over HK in which pollutants in sewage are removed by various treatment processes so as to achieve the discharge requirements as specified in the discharge licences. Location of major STWs is shown in Appendix F. In terms of levels of treatment, preliminary treatment or screening basically removes large particles of 6 mm in diameter and above and grit of over 0.2 mm in size from the sewage. In primary treatment, further removal of pollutants is carried out by sedimentation. The Chemically-enhanced primary treatment (CEPT) plant at Stonecutters Island makes use of chemical additives to speed up and enhance the sedimentation process and, hence, achieves higher and faster removal of pollutants than the normal primary treatment plants. Secondary treatment plants provide biological treatment to sewage in which organic matters are converted to stable substances by bacterial activities. In 2001, we have treated a total of 885 million m3 of sewage. 64.5%, 0.5%, 17.2% and 17.8% of the sewage received preliminary treatment, primary treatment, CEPT treatment and secondary treatment respectively.

The sludge arising from the sewage treatment process is currently dewatered to a minimum of 30% dry solid content before final disposal at sanitary landfills. In 2001/2002, a total of around 197,000 tonnes of dewatered sludge and 21,400 m3 of screenings and grit were disposed of.

In addition to all the proactive measures taken to ensure effective operation of our sewage treatment facilities, the department has designated engineers to carry out research and development work with a view to further improving our services, such as finding solutions for operational problems in sewage treatment, and keeping abreast of the latest technological development in the field. To minimize breakdown of sewage treatment facilities, we have been applying advanced computer software to administer the day-to-day maintenance on the electrical and mechanical equipment in the major sewage treatment works. Proper maintenance of buildings and concrete structures in STWs is equally important and the task is managed by a dedicated team of engineers. Regular inspection and repair, if necessary, of structures is carried out to ensure integrity of structures and proper functioning of the plants. Apart from these, landscaping work including planting of 9,232 trees/shrubs, re-painting of 20 plants and cleansing of 139,520 m2 of structures had been carried out during the year in order to upkeep and beautify the appearance of these plants. |

||||||||||||||||||||||||||||||||||||||||||||||

|

Operations and Maintenance of Submarine Outfalls There are a total of 43 submarine outfalls and two effluent disposal tunnels built for effective discharge of treated effluent in a controlled manner. To prevent pollution of the receiving water bodies caused by the leakage of effluent through cracked submarine outfalls, inspections and maintenance of the outfalls are carried out regularly. One of the effective means adopted for monitoring the performance of the outfalls is by helicopter inspection of dye test on the outfall pipes. Dye tests on these 45 effluent outfalls and tunnels at 24 plants have been carried out during the year, and 17 detected leakage were subsequently repaired. In addition, underwater inspection, hydrographic sounding survey, regular flushing and desilting of outfalls have been carried out as scheduled in a comprehensive preventive maintenance programme.

|

|

|

Harbour Area Treatment Scheme (HATS) In 1989, the Sewage Strategy Study recommended the Strategic Sewage Disposal Scheme [now renamed as HATS] to collect and convey all wastewater from the urban areas surrounding Victoria Harbour through a deep tunnel conveyance system to one or two centralized sewage treatment works for treatment, before final disposal to the waters south of Hong Kong. The Scheme is a major Government initiative to clean up Victoria Harbour and is to be implemented in stages. Stage I focuses on the collection and conveyance of sewage from Kowloon and the northeastern part of Hong Kong Island to Stonecutters Island for centralized treatment, while the furthur stages aim at collecting and treating sewage from the northern and southwestern parts of Hong Kong Island, as well as providing a higher level of treatment for all the sewage in order to meet the environmental standards. Construction of HATS Stage I commenced in mid-1994. It entails the upgrading of seven existing preliminary treatment works and construction of a 23.6 km-long deep tunnel conveyance system, a large-scale sewage treatment works at Stonecutters Island and a 1.7 km-long outfall tunnel, serving a population of 3.5 million people. The deep tunnel conveyance system was adopted not only to allow the shortest route to be chosen but also to minimise the disturbance and nuisance to the public, the environment, utilities, transport systems, etc. during construction. The tunnel system consists of seven deep tunnels of finished diameters from 1.2m to 3.5m and depths at 76m to 143m below sea level, and has a minimum rock cover of 30m. Except for the shortest tunnel section from Kwai Chung to Tsing Yi, which was constructed by drill and blast method, hard rock tunnel boring machines (TBMs) were used for excavating the other six tunnels. Owing to the forfeiture of the original tunnel contracts in December 1996, progress of the tunnel construction had been seriously disrupted. The tunnel progress had also been affected by the adverse geological conditions encountered during excavation. Despite all these problems and difficulties, all tunnels were successfully completed in December 2001 and the Stage I system has since been commissioned and put into full operation. It is now treating over 1.3 million cubic metres of sewage collected via the deep tunnels every day at Stonecutters Island before dispersing the treated effluent into the western harbour through the Stage I Outfall. The Stonecutters Island Sewage Treatment Works adopts a Chemically Enhanced Primary Treatment (CEPT) process and has a capacity for treating 1.7 million cubic metres of sewage each day. It is achieving excellent performance results and is the world's most efficient plant of its kind. Its main underground pumping station is also the largest in Asia having a pumping capacity of 31 cubic metres per second. As for the further stages of the Scheme, the Environmental Impact Assessment Study, completed in 1999, recommended that chemical treatment enhanced by disinfection should be adopted and the effluent be discharged to the east of Lamma Island. However, in view of the public concerns regarding the above development plan, the Government commissioned a second International Review Panel (IRP) to review the proposed scheme. The review was completed in November 2000 recommending that consideration should be given to upgrading the treatment level to a higher standard and discharging the effluent within the harbour areas. On this basis, the IRP suggested four alternative plans with different degrees of centralization of treatment facilities and locations of outfalls for further development of HATS. In response to the IRP's recommendations, a series of studies and trials are now being undertaken to assist in formulating the way forward for the subsequent stages of HATS. These include the environmental and engineering feasibility studies (by EPD) to investigate the viability of the IRP's options, the pilot plant trials (by DSD) to study the application of compact sewage treatment technologies for Hong Kong sewage, and the study on procurement options (by DSD) to identify the most efficient and effective procurement arrangement for implementing the further Stages of HATS. All these studies and trials have commenced and are scheduled for completion by early 2004. |

|

|

Wan Chai East and North Point Sewerage — The Wan Chai East and North Point Sewerage Improvement Works is one of the major Sewerage Master Plan projects. It aims to improve and upgrade the existing sewerage systems in Wan Chai East and North Point to meet development needs up to the year 2021. The works comprise the construction of about 17 km of sewers and a new pumping station and the estimated project cost is $1.6 billion. An essential but a very difficult portion of the works is the construction of two lengths of trunk sewers in some of the busiest roads in Causeway Bay and North Point, a 1 km long sewer along Yee Wo Street, Hennessy Road, Percival Street and Gloucester Road and a 2.7 km long sewer along Electric Road and Java Road. Thus an important consideration in our planning and design of the works is to minimize the impact on traffic as well as the nuisance and inconvenience to the public that may be induced by the construction activities. An effective measure is to construct the trunk sewers by means of trenchless methods which can largely reduce the extent of road opening, and can thus minimize disruption to traffic, businesses and public. It is also more environmental friendly because we can minimize and effectively control the environmental impacts such as noise and dust generated from the construction activities.

Advance Contract Helps Reduce

Risks for the Construction of Trenchless Sewer In order to reduce the risks, costs and time associated with trenchless construction, we have adopted an innovative approach by the use of an advance contract to provide relevant information as much as possible before tendering of the construction contract. In the advance contract, we conduct full-scale trial runs for all agreed temporary traffic schemes to demonstrate their effectiveness and to modify the temporary traffic arrangements if necessary. With the agreed traffic schemes and the finalized locations of shaft sites, we carry out further investigation works to obtain more ground and utilities information, including trial trenches at shaft sites to eliminate the risk of uncharted utilities. We also make advance co-ordination and planning for all utilities diversions that are found necessary. This largely reduces unforeseen risks during construction and minimizes delay to the construction works.

Public Relations Strategy Therefore, we have, prior to tendering of contracts, conducted presentations to the Wan Chai and Eastern District Councils to brief the council members about our proposed works and traffic diversion arrangements in the concerned areas during construction and have obtained their support. We will report regularly to the Councils on the progress during construction. We have also prepared and distributed information leaflets, through District Offices, to the council members and the general public, especially those shop owners and local residents who are likely to be affected by the works. Pictorial signboards have also been placed at predominant locations at the works sites to inform the general public of the progress of proposed works, traffic and/or pedestrian diversion schemes and other relevant information at that particular site. We will regularly update the information to keep the people affected fully informed. After commencement of the contracts, the Resident Engineer and his site staff have established regular contacts with all concerned parties, ie the shop owners and committees of private buildings that might be affected by the works. There is a patrol team specially organised to carry out regular inspection of the works sites to ensure safety and minimum nuisance to the public. A 24-hour hotline has also been set up so that any public concern or complaint can be received and dealt with promptly. In addition to the hotline, the public may also use the feedback forms attached with the information leaflets to provide their feedback on the works. Closures of heavily trafficked roads or footpaths or construction activities in front of shops will never be welcome. However, we have integrated advanced construction technology, innovative contracting strategy and a proactive public communication approach to provide a cost-effective and workable solution in this Wan Chai East and North Point sewerage improvement project. In particular, this is the first time DSD has introduced an advance contract prior to tendering of the main works. We have achieved a significant reduction in the contract sum of the main works contract. The construction works had started in May 2002 and are scheduled for completion in early 2006. |

|