Stonecutters Island Sewage Treatment Works

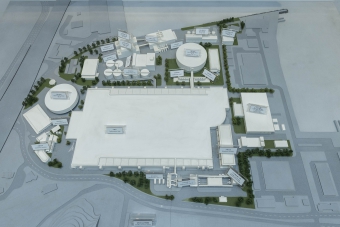

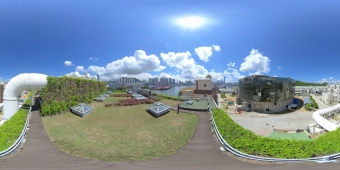

Occupying 10 hectares of reclaimed land, Stonecutters Island Sewage Treatment Works (SCISTW), is a chemically enhanced primary treatment works with design flow of 2,450,000 cubic metres per day, equivalent to the volume of about 1,000 Olympic-size swimming pools. It is one of the largest and compactest sewage treatment works of its type in the world and also forms an important part of the Harbour Area Treatment Scheme (HATS). SCISTW was fully commissioned in December 2001. It is treating about 1,900,000 cubic metres sewages from either side of Victoria Harbour every day.

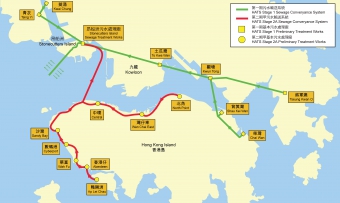

HATS is the largest environmental infrastructure project in Hong Kong, aiming to improve the water quality of Victoria Harbour by collecting and treating sewage generated from both shores. The project was implemented in stages. Stage 1 was commenced in 1994 and commissioned in December 2001, with major works comprised of the construction of SCISTW; construction of about 23 kilometres of deep tunnels conveying sewage collected from Kowloon and north-eastern Hong Kong Island to SCISTW for chemically enhanced primary treatment (CEPT); and upgrading seven Preliminary Treatment Works (PTWs) at Kowloon and north-eastern Hong Kong Island (Tsing Yi, Kwai Chung, To Kwa Wan, Kwun Tong, Tseung Kwan O, Shau Kei Wan, and Chai Wan). Stage 2A was commenced in 2009 and commissioned in December 2015, with major works comprised of the construction of 21 kilometres of deep tunnels conveying sewage collected from northern and south-western Hong Kong Island to SCISTW for CEPT; upgrading eight PTW in northern and south-western parts of Hong Kong Island (North Point, Wanchai East, Central, Sandy Bay, Wah Fu, Cyberport, Ap Lei Chau and Aberdeen); and upgrading the daily treatment capacity of SCISTW to 2,450,000 cubic metres and construction of disinfection facilities.

After the commissioning of HATS Stage 2A, all sewage from either side of Victoria Harbour is now collected, treated and disinfected prior to discharge. As a result, over 99% of E. coli, 70% of biochemical oxygen demand and 80% of suspended solids are eliminated from the sewage, and the water quality of Victoria Harbour is significantly improved.

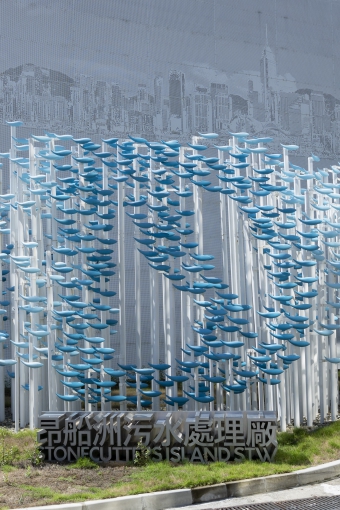

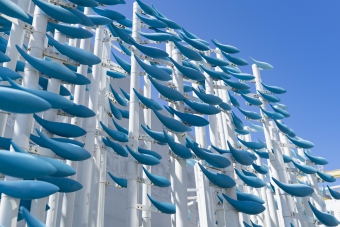

To celebrate the 30th anniversary of the establishment of the Drainage Services Department (DSD) and to commemorate the largest environmental infrastructure project in Hong Kong – Habour Area Treatment Scheme (HATS), DSD has designed a feature wall at the Stonecutters Island Sewage Treatment Works.

The featured wall is named "Fish・1989", which embodies 1,989 fish swimming unison towards the forming of iconic DSD logo. It represents that DSD has kept on providing world-class wastewater and stormwater drainage services to the public since the establishment in 1989. Since the commissioning of HATS Stage 1 and Stage 2A in 2001 and 2015 respectively, the water quality of Victoria Harbour has also been improved significantly.

When sewage collected by the 17 preliminary treatment works on both sides of Victoria Harbour arrives at Stonecutters Island Sewage Treatment Works (SCISTW), it is pumped from the deep tunnels to the surface via Main Pumping Station No.2, one of the World’s largest underground sewage pumping stations. With an internal diameter of 55 metres and a depth of 40 metres., the new pumping station houses eight sets of mega-size sewage pumps, each with a rated pumping capacity of 4.4 cubic metres per second, equivalent to filling up an Olympic-size swimming pool within a minute.

The new main pumping station is also equipped with a multi-function room, which can be used for staff meeting and also receiving local groups and organizations from mainland and overseas to introduce the departmental sewage treatment work to the public.

Sewage siphoned above ground will be pumped to the sedimentation tanks for chemically enhanced primary treatment. Chemicals (ferric chloride and polymer) are injected at the inlet at required dosages and mixed with the sewage inflow in rapid mixing chambers. The flow passes through flocculation tanks to form flocs. It is then distributed along a main distribution channel into banks of sedimentation tanks. The flocs settle in the sedimentation tanks as sludge which are removed by chain and flight sludge collectors and then pushed to sludge hoppers. The lighter foam and floatable solids rising to the surface are known as scrum which are skimmed off by scum collectors. The sludge, together with the scum, are pumped to a separate facility for dewatering. The process removes about 80% of the suspended solids and 70% of the Biochemical Oxygen Demand.

The treated effluent from sedimentation tanks are disinfected by dosing sodium hypochlorite solution at the Flow Distribution Chamber and enter the Effluent Tunnel for 30 minutes for disinfection. The effluent would then be de-chlorinated by sodium bisulphite solution before discharge into the western part of Victoria Harbour at the submarine outfall.

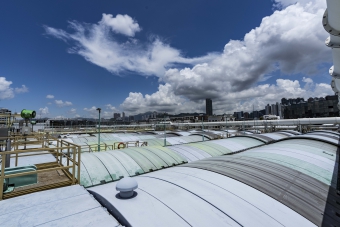

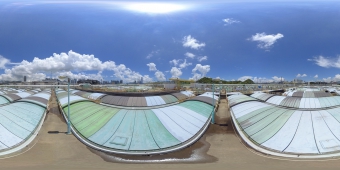

SCISTW adopts a double-decked sedimentation tank design to reduce the entire plant’s footprint. Despite that the 10 hectares land occupied SCISTW is only about half of the size of Victoria Park, it can serve up to 5.7 million people on both sides of Victoria Harbour.

To act proactively in an environmental manner and to provide a better service to the nearby residents, mitigation measures for odour control are taken at the existing sedimentation tanks of SCISTW, including: installation of fibreglass reinforced plastic covers with a gas-seal design on the existing sedimentation tanks, flow channels and chambers; installation of an air extraction system to collect foul gas within the covered facilities; and treatment of foul gas by “Chemical Scrubbers” and "Biotrickling Filter" technology before discharge into open air.

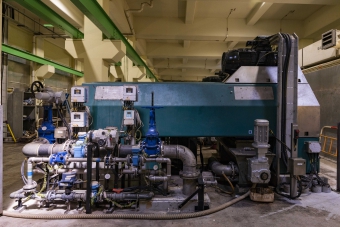

Sludge dewatering facilities were added to handle up to 1,200 tonnes of sludge per day, with 14 centrifuges raising the solid content of the sludge from 2% to a minimum of 32%. Two special vessels were also built to deliver sludge from Stonecutters Island Sewage Treatment Works to a sludge treatment facility T・PARK in Tuen Mun, minimising the potential odour nuisance to nearby residents caused by land transport.

“Clean Harbour 1” and “Clean Harbour 2” are the first diesel-electric propulsion container vessels in Hong Kong. They are connected to on-shore power supplies when berthed, without using diesel and thereby achieving zero emission, which improve the air quality at the shore. Compared to regular vessels, the carbon dioxide emission from the two sludge vessels are reduced by 130 tonnes every year, which is equivalent to the amount absorbed by 6,000 trees over the same period.

For details about Stonecutters Island Sewage Treatment Works (SCISTW) and Harbour Area Treatment Scheme (HATS), please visit the following website: