Core Responsibilities

Planning, Design and Construction of New Sewerage Facilities

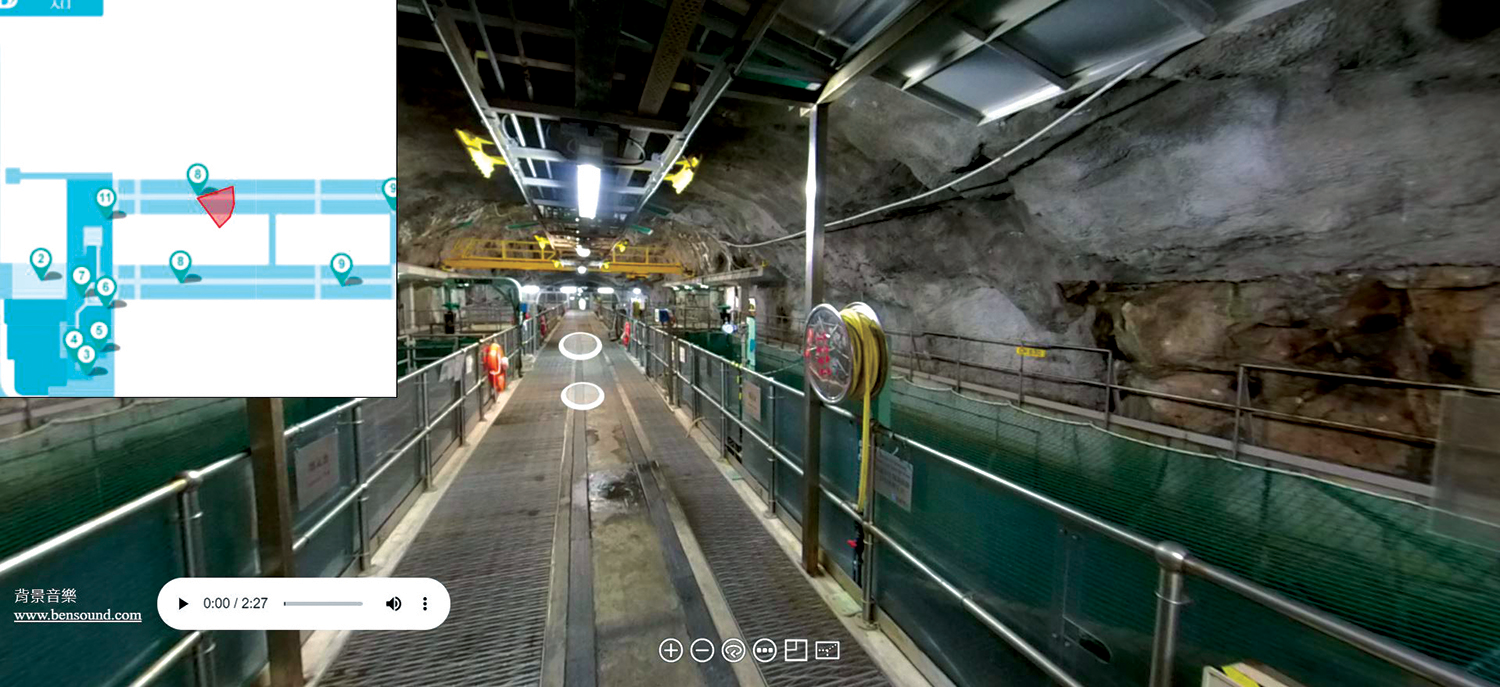

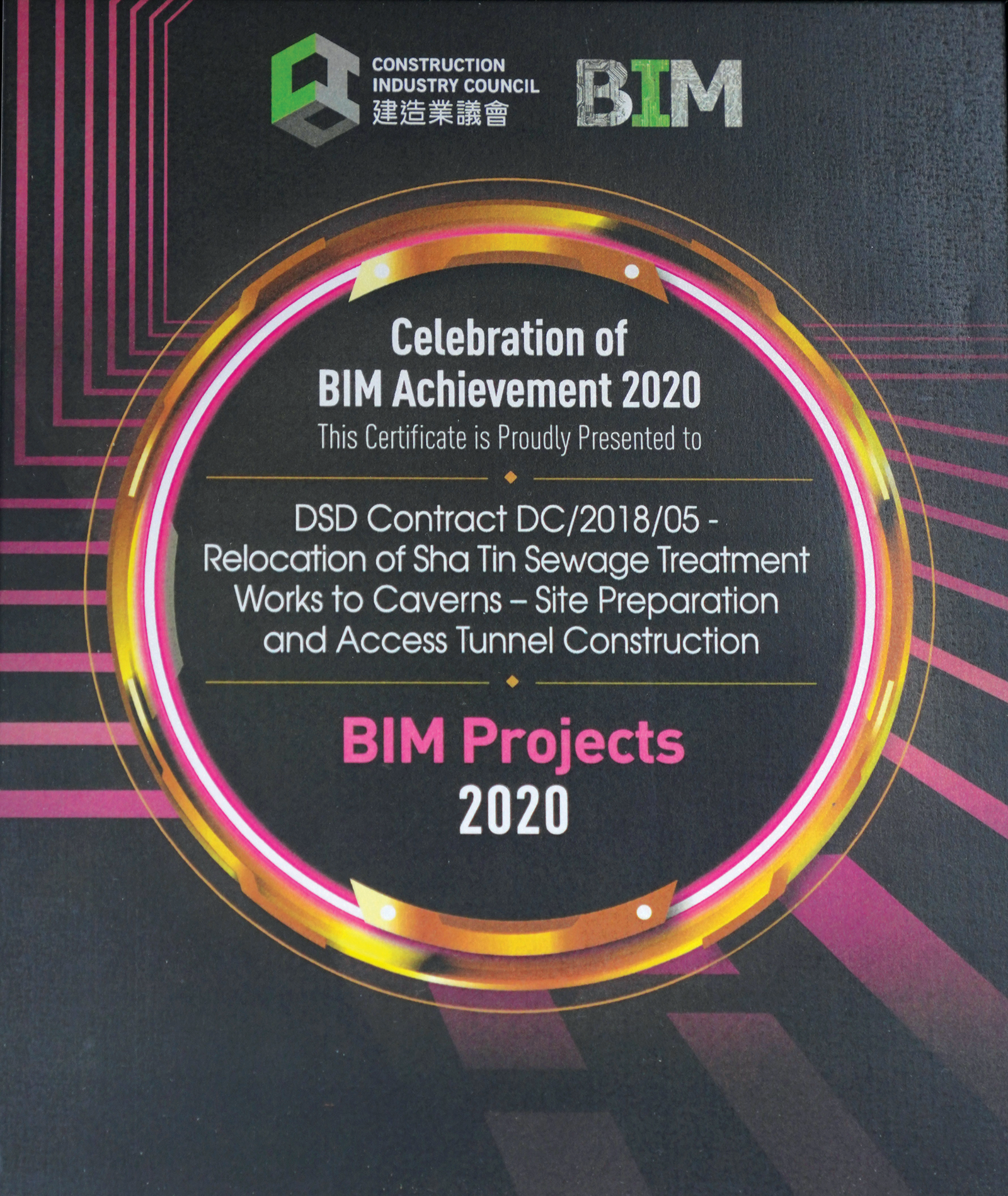

“Relocation of Sha Tin Sewage Treatment Works to Caverns” project

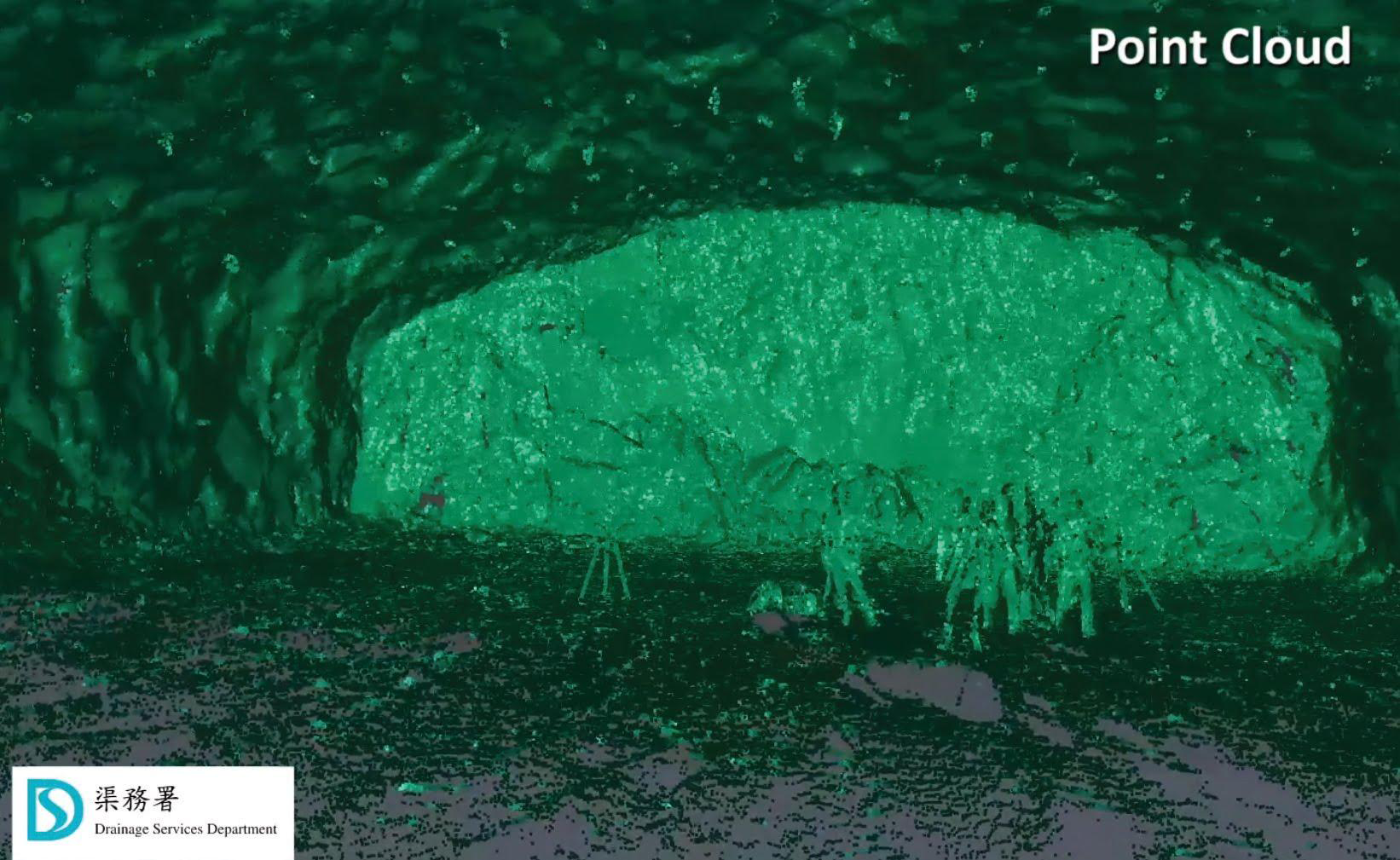

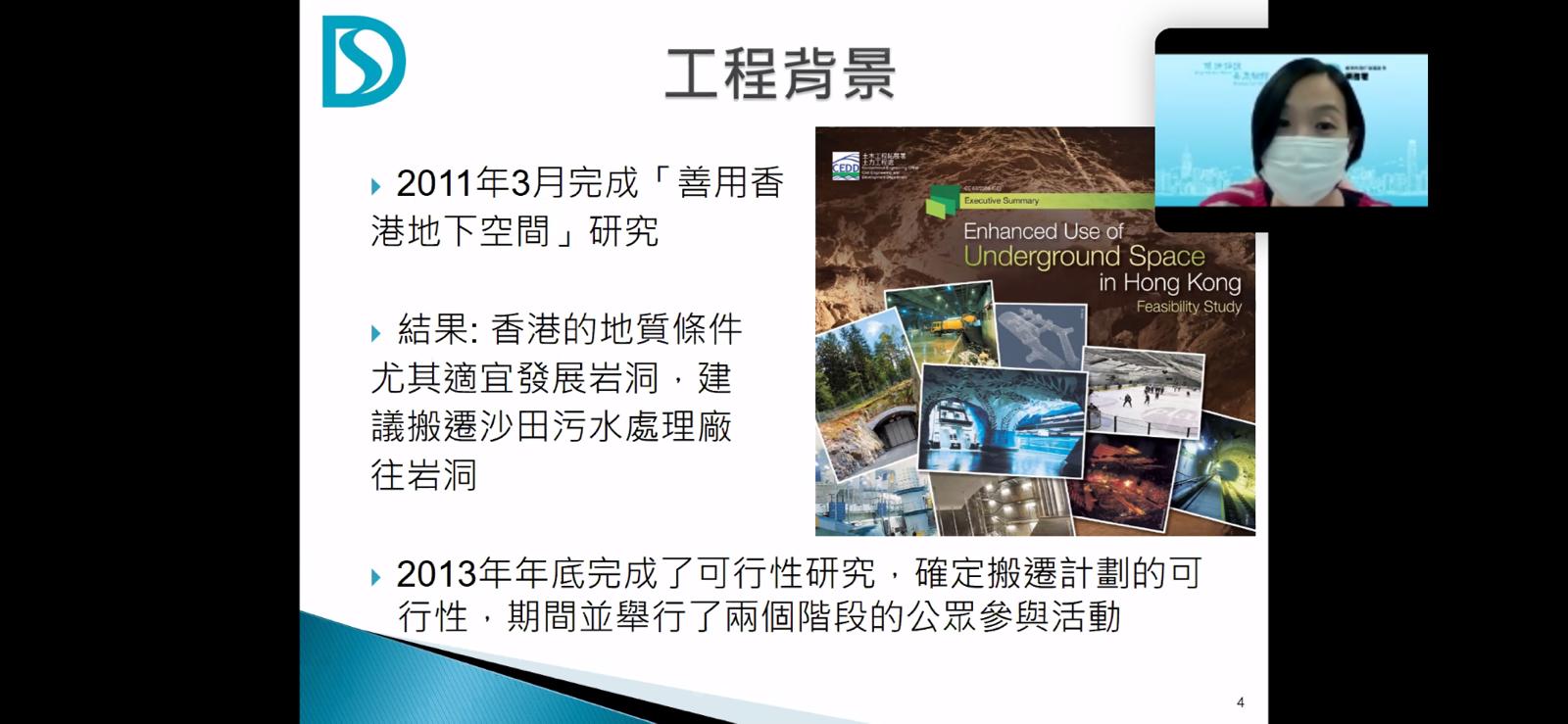

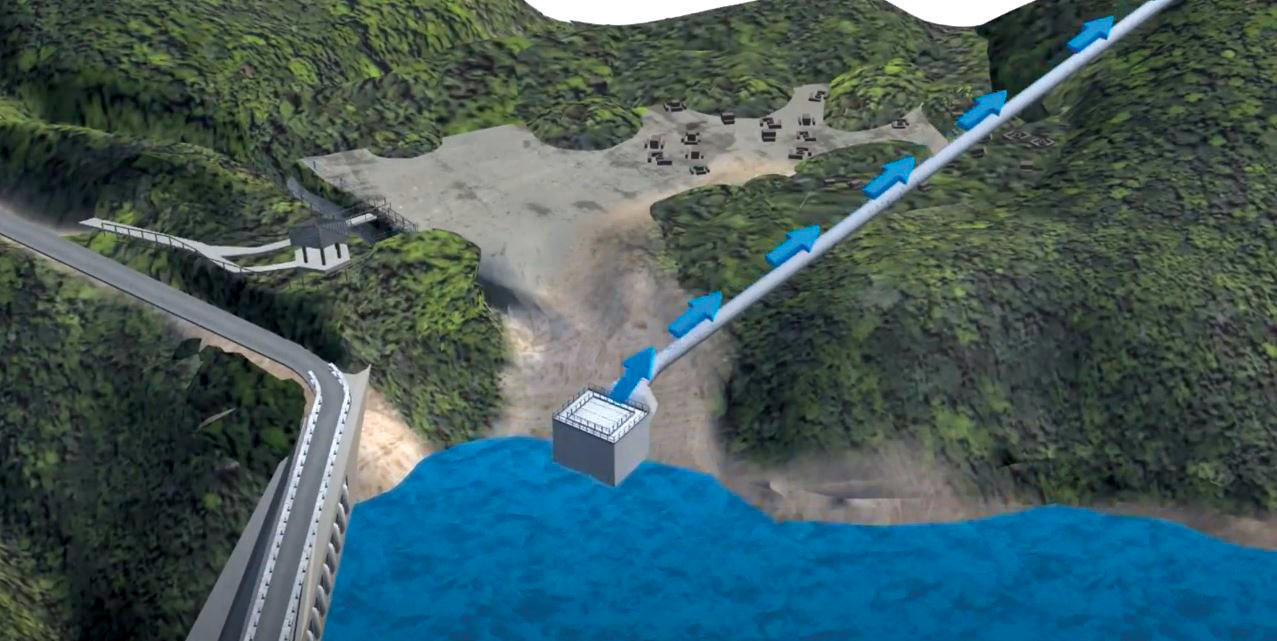

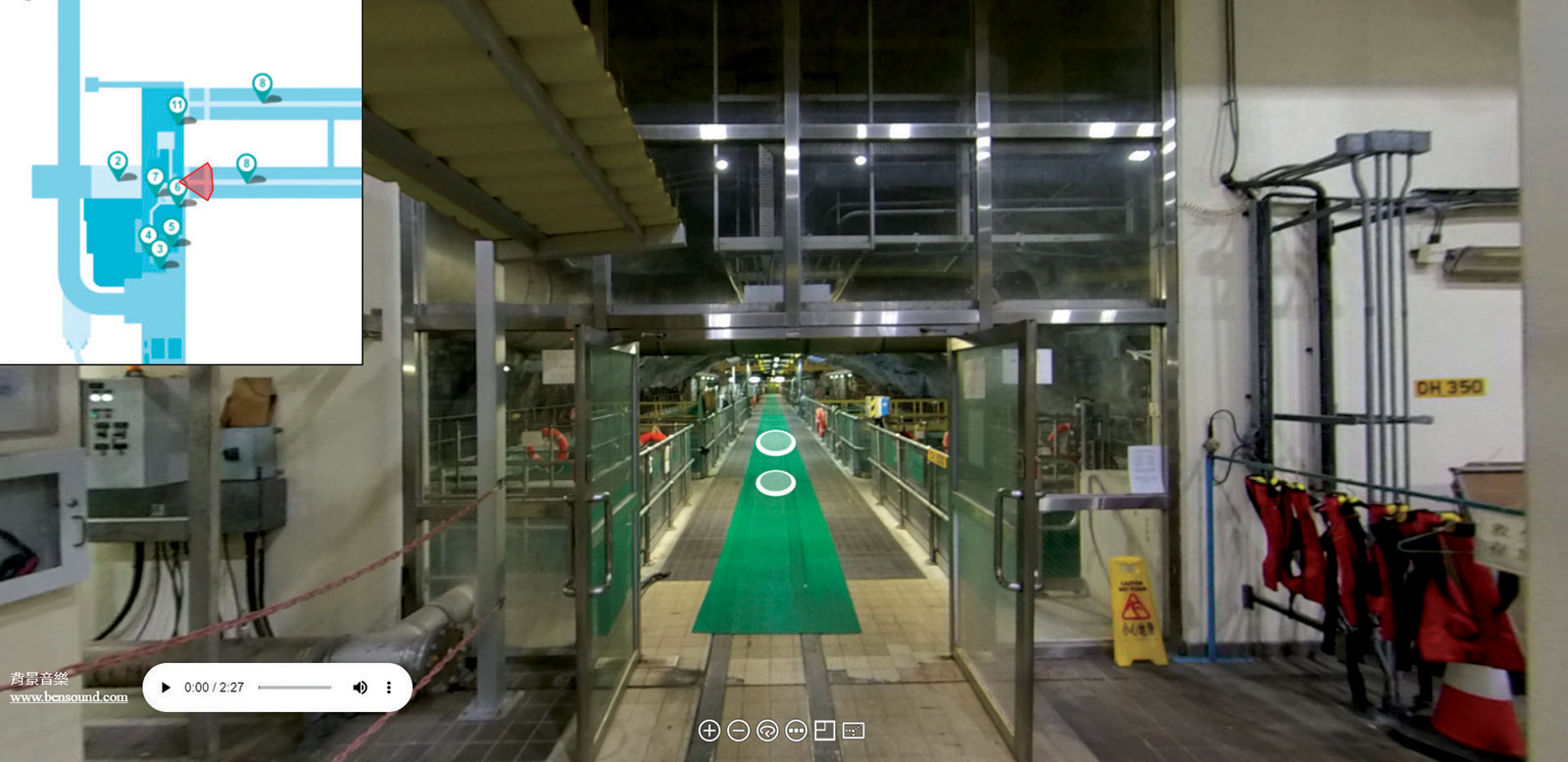

To meet Hong Kong’s high demand for land for long-term development, the Government is actively developing caverns to expand land resource. In support of the Government’s development plan, the DSD is carrying out relocation works to move Sha Tin STW to the excavated caverns in Nui Po Shan across Shing Mun River. The caverns serve as natural barriers for the future STW, thereby enhancing odour management to minimise the odour impact on nearby residents. Also, about 28 hectares of land on the site of the existing Sha Tin STW will be released and planned for other beneficial and needed uses for improving the living environment in Sha Tin.

Upon completion, the new Sha Tin STW in caverns is anticipated to be the largest of its kind in Hong Kong, with an estimated daily treatment capacity of about 340,000 cubic metres. The relocation project involving site preparation and access tunnel construction, main caverns construction and upstream sewerage works, sewage treatment facilities installation, as well as decommission and demolition of the existing Sha Tin STW, will be implemented in stages. The entire project is expected to take about 13 years to complete.

Current Progress

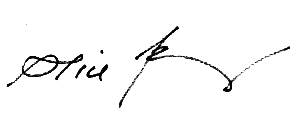

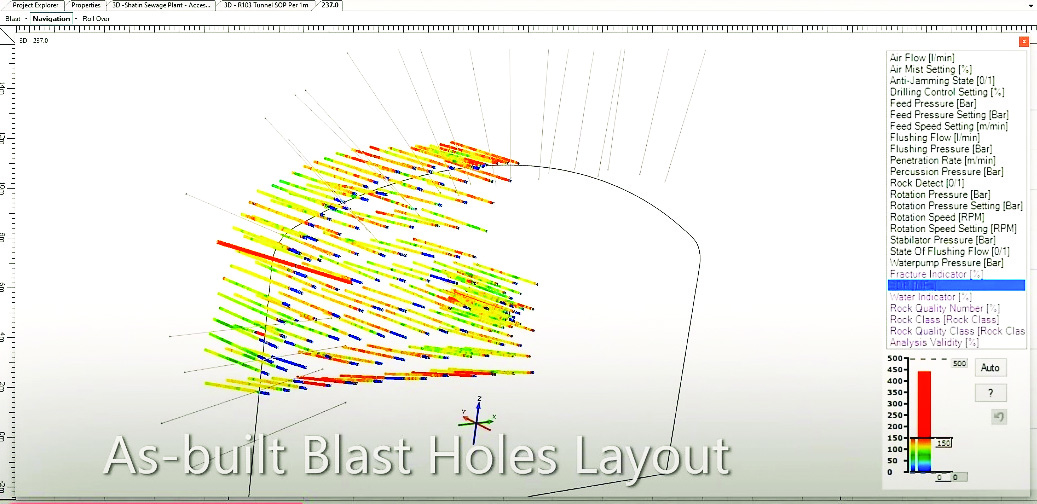

The project’s design work has been completed in phases since 2017. Stage 1 works, which include site formation, construction of access tunnel and retaining structures as well as associated road works, commenced in February 2019 and are expected to be completed in 2022 as scheduled. For Stage 2 works which include construction of the main caverns complex and upstream sewerage works, funding was approved by the Finance Committee of the Legislative Council in January 2021 and construction works commenced in July 2021. The DSD is working on the detailed design of the remaining works and pushing forward with the project.

Stage 1 works of “Relocation of Sha Tin Sewage Treatment Works to Caverns”

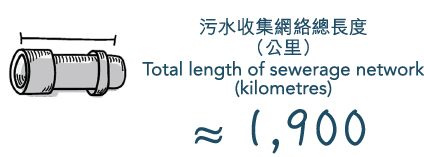

Harbour Area Treatment Scheme (HATS)

To improve the water quality of Victoria Harbour by collecting and treating sewage from both sides of the Harbour, the HATS had been carried out in two phases since 1994. As the largest ever environmental infrastructure project in Hong Kong, with a total cost of $25.8 billion, the construction works spanned over two decades. The facilities of HATS Stage 1 and Stage 2A were fully commissioned in December 2001 and December 2015 respectively. We will carry out a study to review the performance of the HATS system, assess the operational condition of different system components and draw up recommendations to enhance the HATS system and facilities.

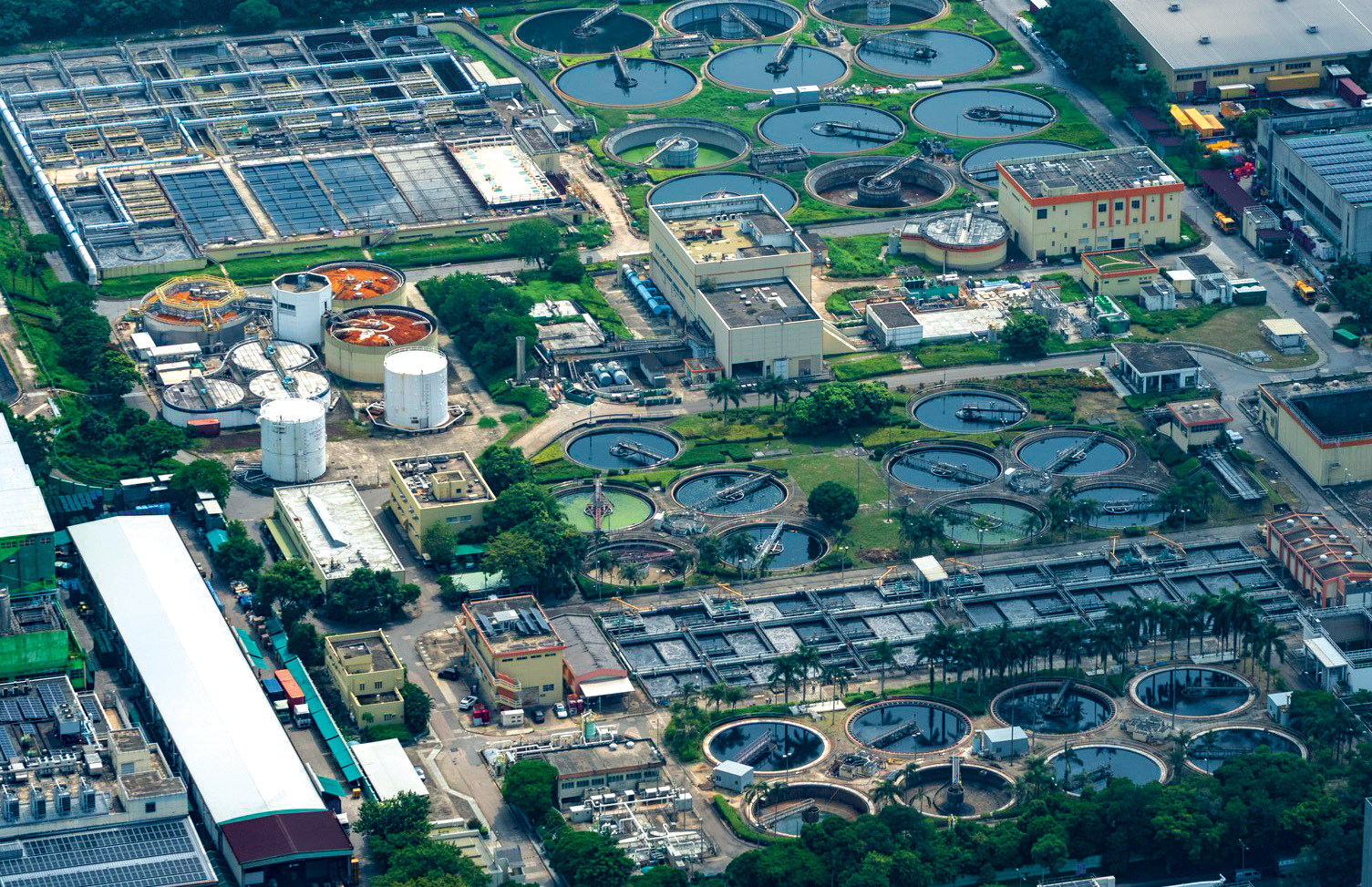

Stonecutters Island Sewage Treatment Works

Current Progress

Feasibility study on HATS system management commenced in May 2020 and has almost completed. Detailed studies would be followed and would be conducted in three phases. The 1st phase would cover the detailed investigation of the system and facilities enhancement works for six preliminary treatment works at the harbour sides, with the target to commence in mid-2022.

Shek Wu Hui Effluent Polishing Plant

In response to district development and public expectations of continuous environmental betterment, we are planning to transform the existing Shek Wu Hui STW, which has been in operation for more than 30 years, into Shek Wu Hui Effluent Polishing Plant. The project involves gradually upgrading the facility to tertiary treatment level and expanding the sewage treatment capacity of the plant from 93,000 cubic metres per day to 190,000 cubic metres per day in phases to ensure that its discharge will conform with more stringent environmental requirements, thus protecting the ecological environment of Deep Bay. In the future, we will also add appropriate landscape facilities and a riverside promenade to improve the appearance of the plant, so as to enhance its role as an educational site for water conservation and make the plant a multipurpose community facility.

Shek Wu Hui Sewage Treatment Works Improvement Works

Current Progress

The advance works of Shek Wu Hui Effluent Polishing Plant commenced in mid-2015. A group of conventional secondary sewage treatment facilities with a capacity of 20,000 cubic metres was converted into a membrane bioreactor with a capacity of 40,000 cubic metres. These facilities have been in operation since December 2019. The main works are being implemented currently in three phases. The first phase started in the third quarter of 2019 and the final phase is scheduled for completion in 2034. The estimated cost for the advance works, investigation and design is about $500 million, while the estimated cost for the main works comes to about $13.2 billion.

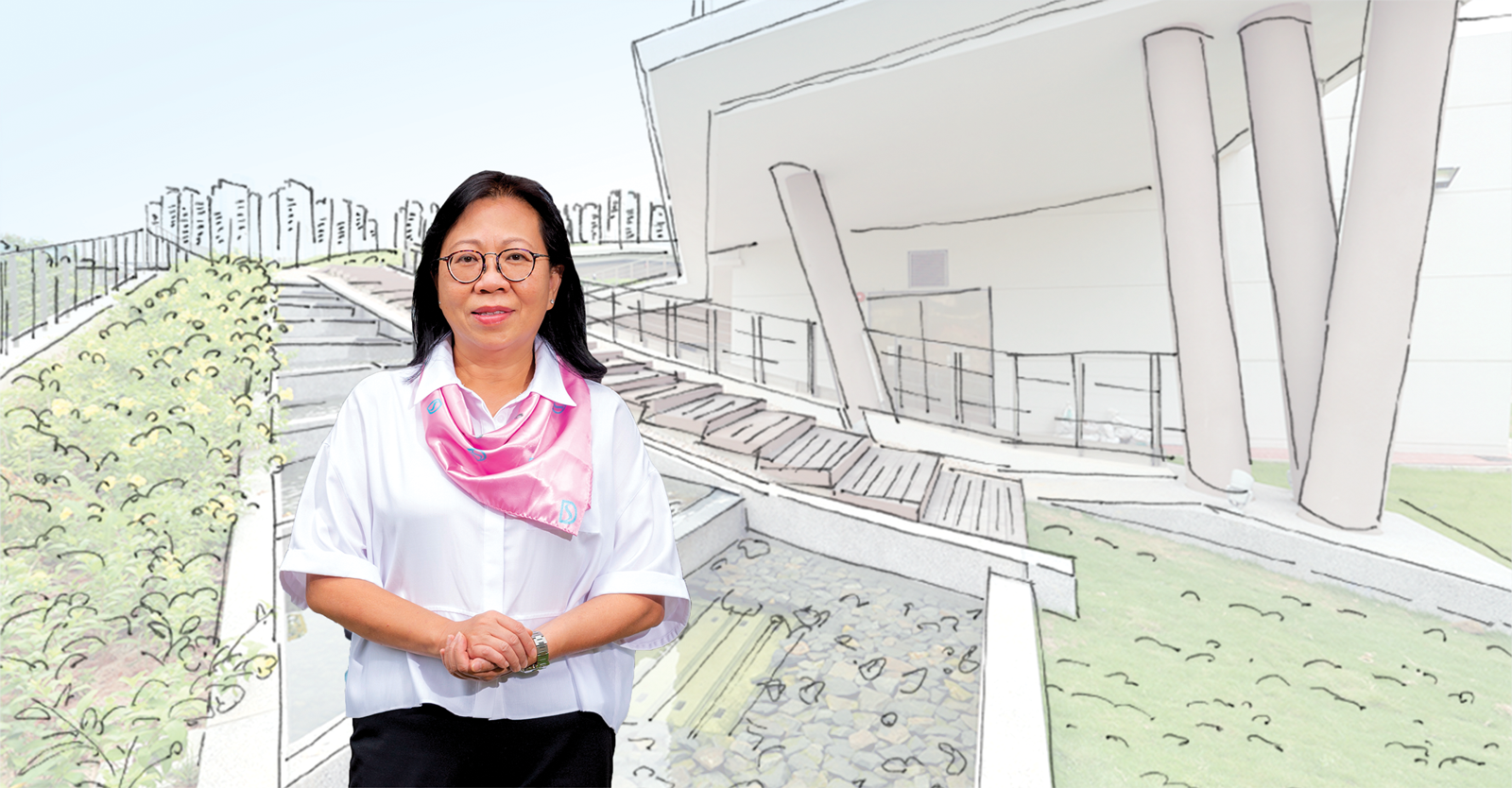

Yuen Long Effluent Polishing Plant

Currently, Yuen Long STW serves Yuen Long Town, Yuen Long Industrial Estate and Kam Tin areas with treatment capacity of 70,000 cubic metres per day at secondary sewage treatment level. To cope with the population growth and development needs, we will upgrade the treatment capacity of Yuen Long STW in stages to 150,000 cubic metres per day. The sewage treatment level will also be upgraded to tertiary treatment level, improving the effluent quality to meet the more stringent discharge requirements, thus minimising adverse environmental impact on the ecological setting of Deep Bay. Also, the plant will use renewable energy to enhance environmental performance. Moreover, we adopt substantial greening features to beautify the plant’s exterior, and public co-use facilities will be in place to benefit the local community.

Photomontage of the Yuen Long Effluent Polishing Plant

Current Progress

The upgrading works will be implemented in two stages. The construction of Stage 1 Works commenced in November 2020 for completion in 2027. Estimated cost for Stage 1 Works is about $6.9 billion while the budget for investigation and design is approximately $89 million.

Expansion of Sha Tau Kok Sewage Treatment Works Phase 1

We expect short-term increase in the sewage volume of various areas in Sha Tau Kok, including Sha Tau Kok Town, Yim Liu Ha, Tsoi Yuen Kok and Sha Tau Kok Chuen. As such, the DSD has planned to redevelop Sha Tau Kok STW in situ to increase its sewage treatment capacity from about 1,660 cubic metres per day to about 5,000 cubic metres per day to cope with surging sewage volume. The project includes the construction of a submarine outfall which is approximately 1.7 kilometres in length and 450 millimetres in diameter, and the replacement of the existing sewage pumping station and rising mains with new gravity sewers.

Being the first “Construction 2.0” pilot project of the DSD, this expansion deployed a number of advanced techniques, namely, off-site construction, smart infrastructure and BIM techniques. In line with the direction of “innovation, professionalisation and revitalisation”, we will strive to enhance construction efficiency, project quality and safety management.

Photomontage of the completed Expansion of Sha Tau Kok Sewage Treatment Works Phase 1

Current Progress

Construction works commenced in November 2018 for completion in 2025. Estimated project cost is about $2.04 billion. To maintain sewage treatment in the service area during construction, the contractor is required to build temporary sewage treatment facilities.

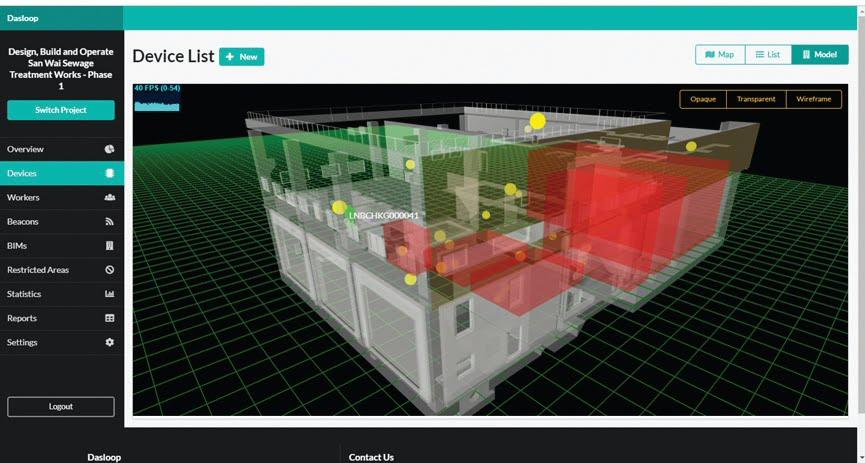

Upgrading of San Wai Sewage Treatment Works Phase 1

The local population of Yuen Long, Tin Shui Wai and Hung Shui Kiu has seen continuous growth in recent years, leading to an increase in sewage discharge. To cope with this situation, the DSD has implemented works to upgrade San Wai STW. Its treatment capacity has been increased from about 164,000 cubic metres per day to

about 200,000 cubic metres per day, while its sewage treatment level has also been upgraded from preliminary treatment to chemically enhanced primary treatment with ultraviolet disinfection. This project is instrumental in improving the quality of Hong Kong’s northwestern waters.

Aerial view of San Wai Sewage Treatment Works

Current Progress

Under the terms of a “Design, Build and Operate” contract, the project was launched in May 2016 and started handling sewage in September 2020. The contractor is now undertaking the operation and maintenance of the new San Wai STW for 10 to 15 years. Estimated project cost is about $3.14 billion.

Upgrading of Cheung Chau Sewage Treatment and Disposal Facilities

Sewerage network expansion is planned for Cheung Chau in the future to link the existing network to additional areas on the island. In preparation for this upcoming project, the DSD is conducting improvement works at Cheung Chau STW by constructing additional treatment facilities to increase its sewage treatment capacity from 4,000 cubic metres per day to 9,800 cubic metres per day. The sewage treatment level will be upgraded from primary to secondary.

Photomontage of the completed Improvement Works at Cheung Chau Sewage Treatment Works

Current Progress

Construction works commenced in November 2020 for completion in 2026. Estimated project cost is about $2.61 billion

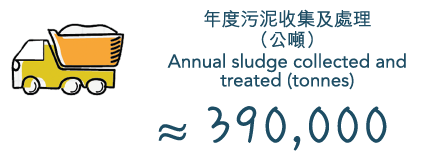

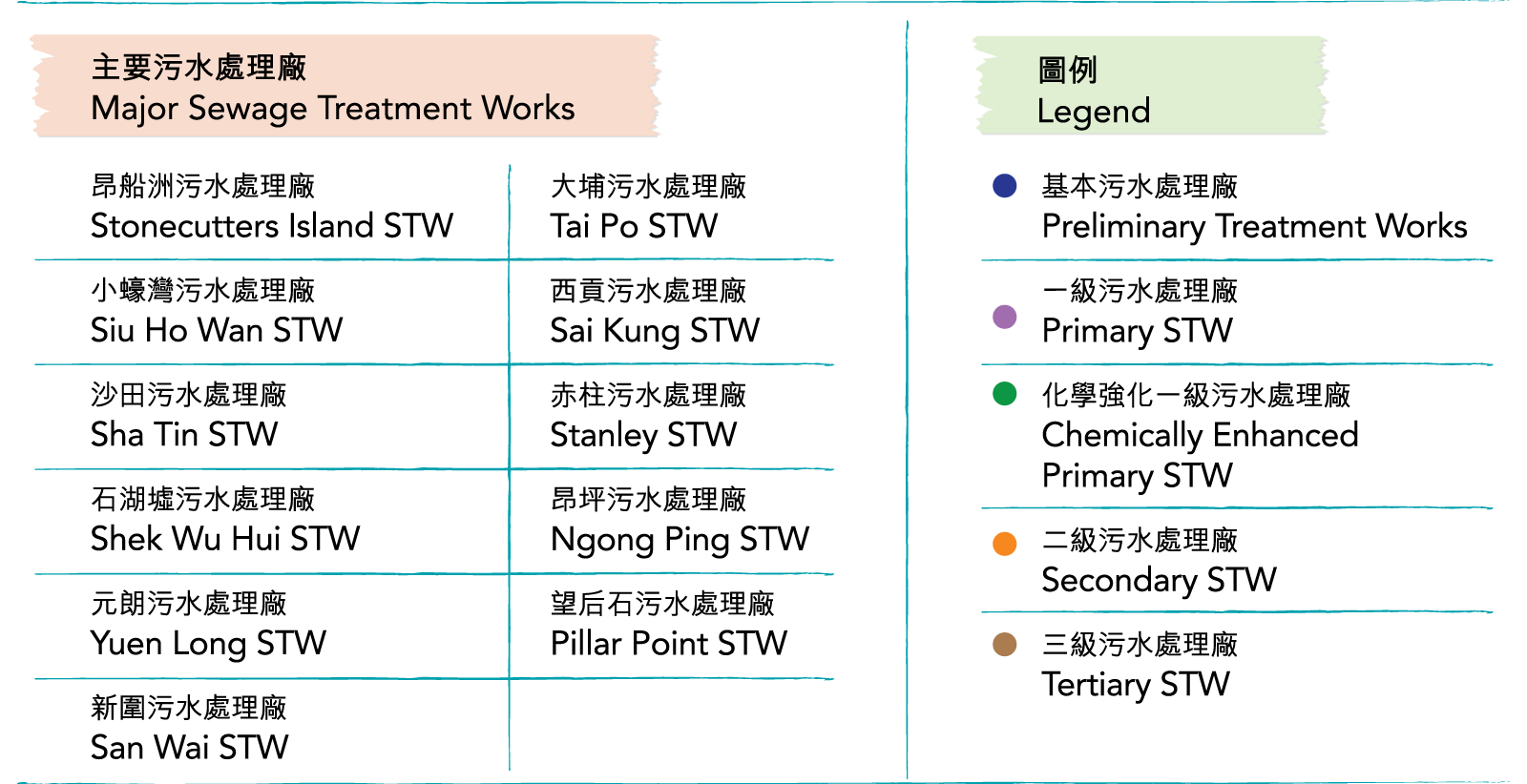

Professional Laboratory Services

To ensure compliance of its sewage treatment service with relevant statutory requirements, the DSD collects and delivers sewage samples for its laboratory tests on a regular basis. The DSD’s laboratories adopt the Laboratory Information Management System (LIMS) and business intelligence software to make sure the effluent quality is up to the discharge standards stipulated by the EPD.

For instance, Sha Tin Central Laboratory has adopted automatic analysers to conduct speedy, accurate and comprehensive tests on the nutrients, trace metal elements and biochemical oxygen demand (BOD) levels of sewage. This laboratory was accredited for testing environmental samples (i.e. samples of water and wastewater) under the Hong Kong Laboratory Accreditation Scheme (HOKLAS) in 1999 and became the first laboratory in Hong Kong to be granted HOKLAS accreditation for BOD tests using an automatic BOD analyser in 2017. Keeping up with the times, the Sha Tin Central Laboratory completed its quality system’s transition to the latest ISO/IEC 17025:2017 – “General requirements for the competence of testing and calibration laboratories” through the Hong Kong Accreditation Service (HKAS) in September 2020.

Currently, Sha Tin Central Laboratory is accredited for conducting up to 32 types of tests. During the year, in response to the COVID-19 pandemic, the DSD adjusted the work arrangement for its staff accordingly, resulting in a 15% decrease in the total number of analyses conducted by the laboratory. Yet, we managed to complete more than 205,000 analyses. The results of analyses of the quality of effluent discharged from major STWs are available on the DSD’s website and the data.gov.hk portal for public reference.

Construction of Dry Weather Flow Interceptors (DWFIs)

Polluted dry weather flow discharged into the stormwater drainage system not only affects the water quality of water bodies nearby, but also causes odour. To avoid the nuisance of unpleasant odour to the surrounding environment and residents, we are building an underground DWFI on the shore of New Yau Ma Tei Typhoon Shelter, which is capable of intercepting polluted dry weather flow at Cherry Street box-culvert and transmit to Stonecutters Island STW for pre-treatment before discharge to reduce unpleasant odour. In addition, we are building four DWFIs in Kowloon West and four DWFIs along the Tsuen Wan coast respectively, and conducting modification projects at 39 existing DWFIs in Kowloon West, in a bid to reduce odour and prevent adverse impact on water quality

Photomontage of dry weather flow interceptor at Cherry Street box culvert

Current Progress

The DSD is currently executing construction and improvement works of DWFIs at Tai Kok Tsui, Kowloon West and Tsuen Wan respectively. Construction works of the DWFI at Cherry Street box culvert in Tai Kok Tsui commenced in December 2017 for completion in 2022. Estimated project cost is about $660 million. In addition, Phase 1 of upgrading works of West Kowloon and Tsuen Wan sewerage commenced in September 2017. Four DWFIs in Tsuen Wan and two DWFIs in West Kowloon were completed in September 2019 and January 2021 respectively while the modification works of DWFIs in West Kowloon were partially completed. The remaining works are scheduled for completion in mid-2022. Estimated project cost is about $280 million.

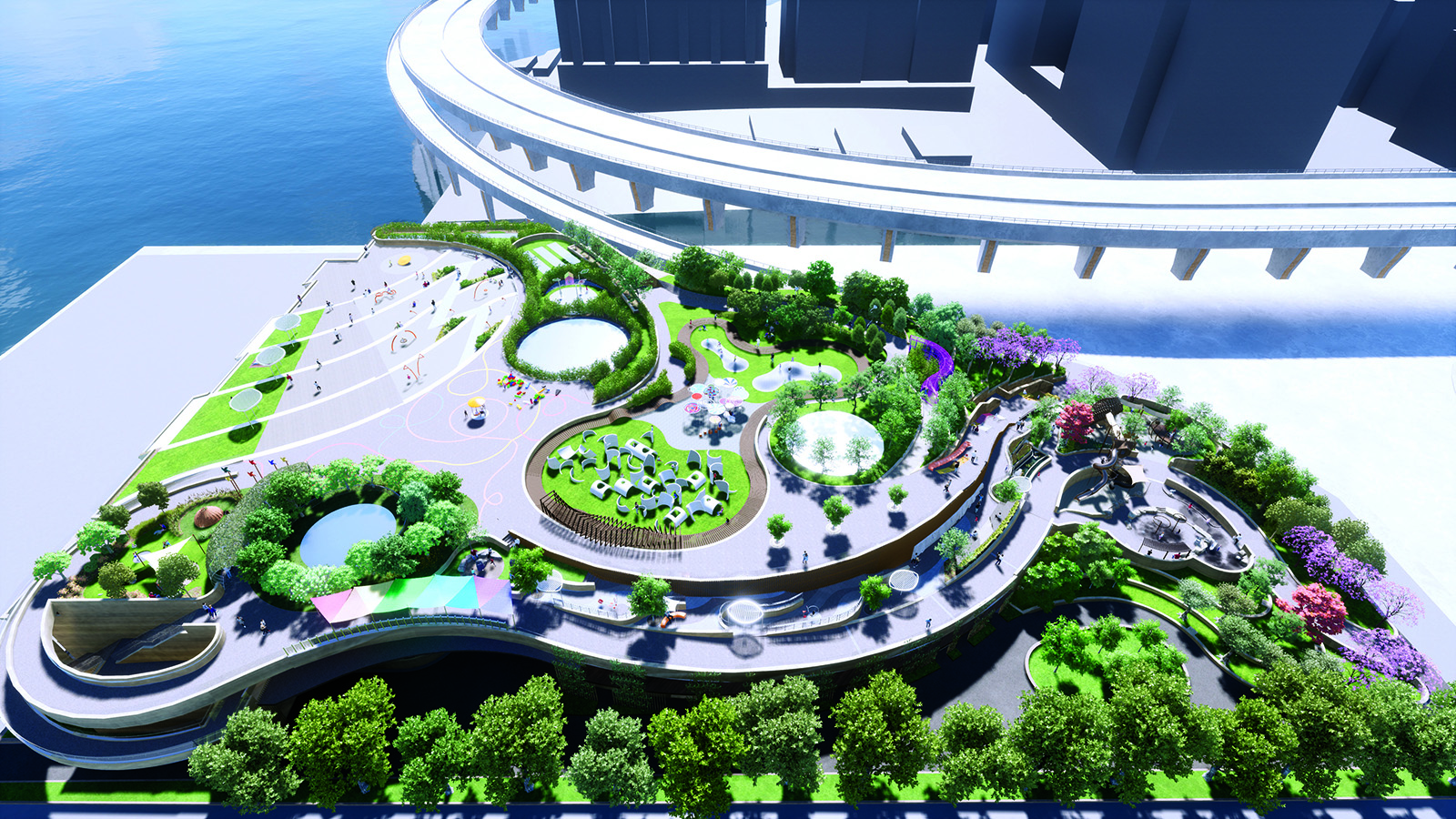

Enhancement Works for Kwun Tong Sewage Pumping Station

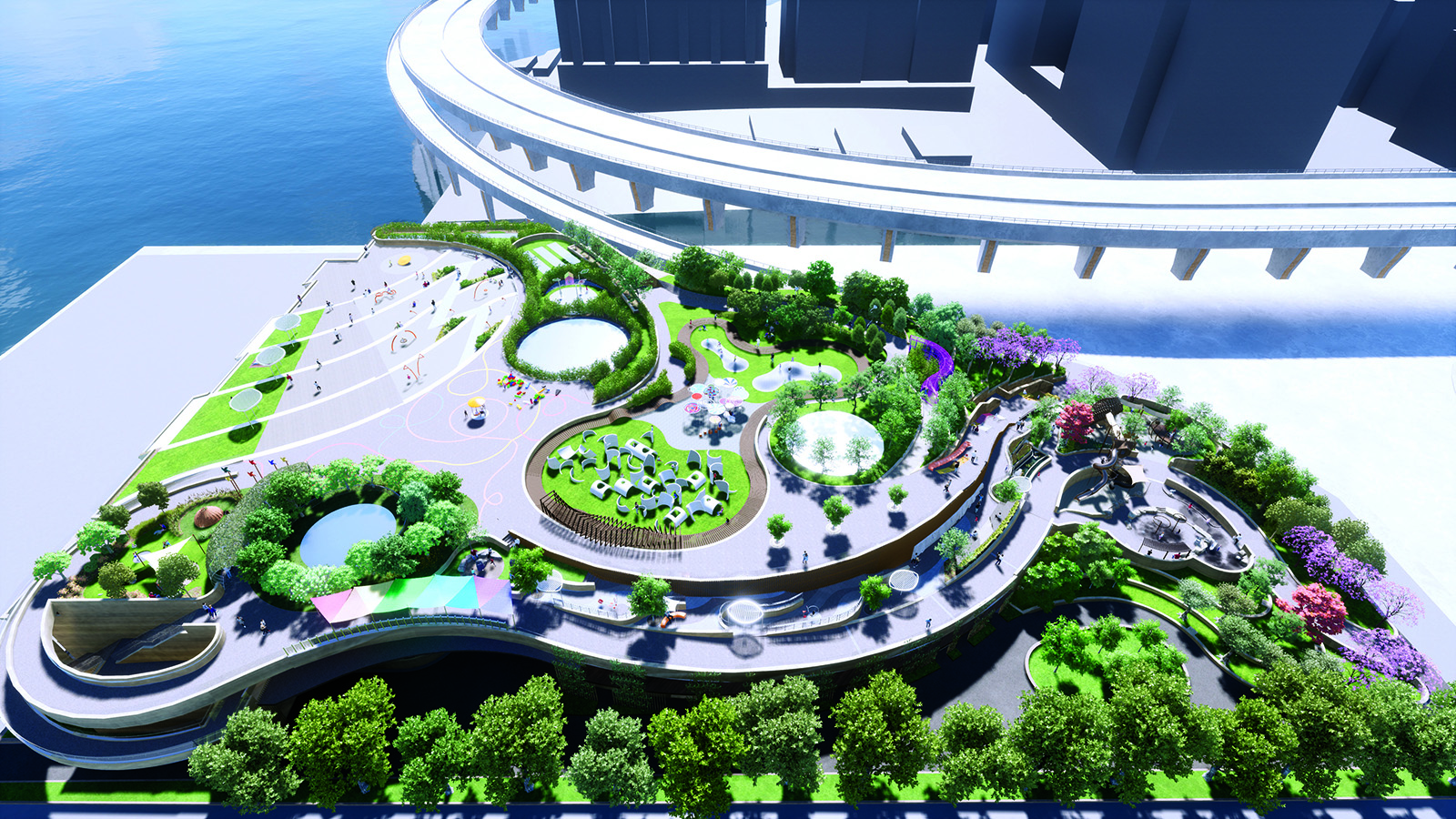

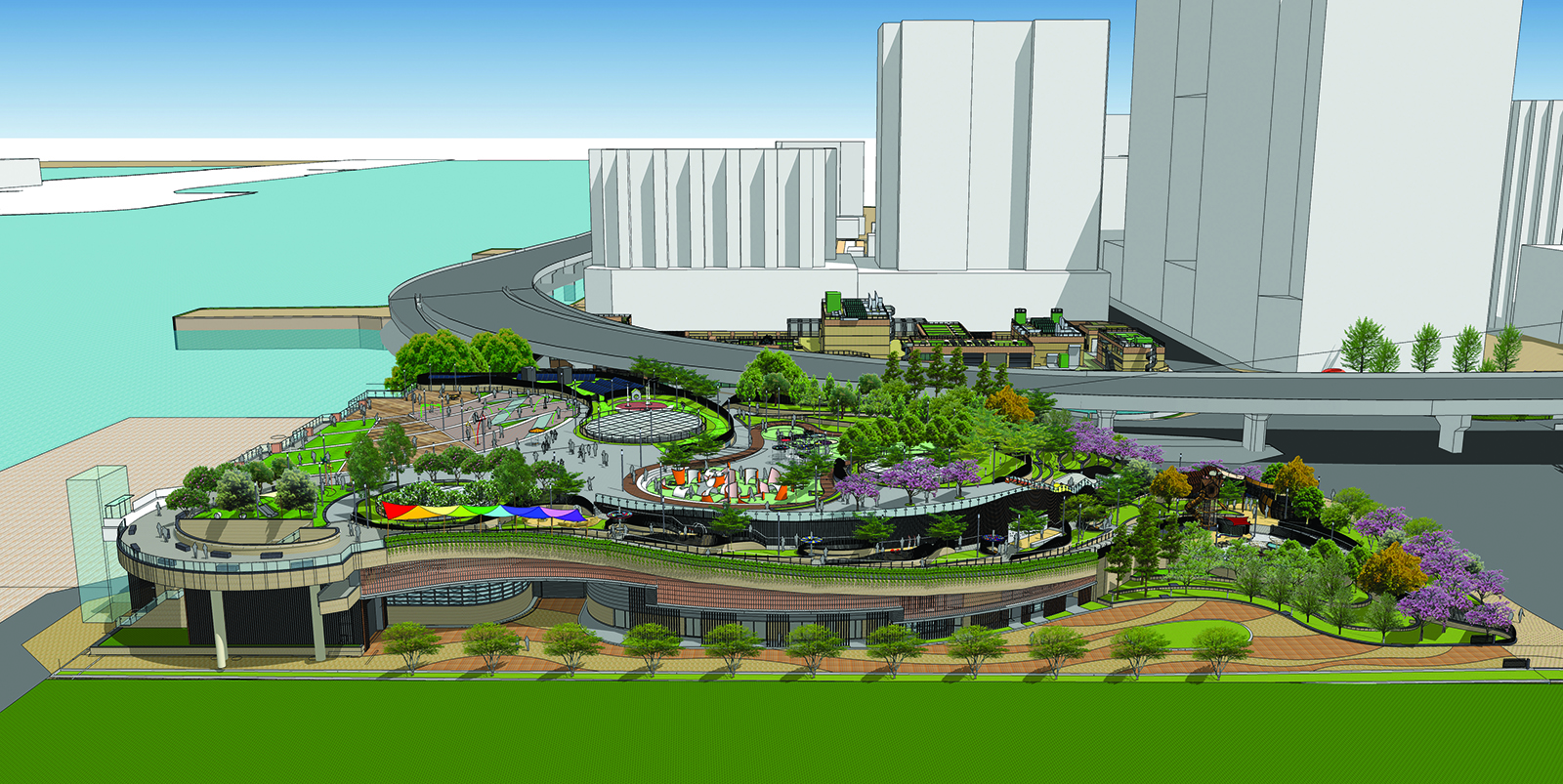

The DSD makes every effort to improve the facilities and environment of its sewage pumping stations (SPSs). In particular, we are conducting enhancement works for Kwun Tong SPS to support the local development of East Kowloon district. Items include constructing a new underground sewage balancing facility with a capacity of 16,000 cubic metres and installing ventilation and de-odourisation facilities. The roof of the pumping station will also be renovated into a public landscaped deck to enhance visual appearance of the pumping station and provide an open space of about 11,000 square metres.

Photomontage of the landscaped deck above the Kwun Tong Sewage Pumping Station

Current Progress

Apart from traditional cast in-situ methods, the project is also adopting the Design for Manufacture and Assembly (DfMA) method which can increase construction efficiency and shorten the construction period by using pre-assembled components. Construction commenced in December 2017 for completion in end-2022. Estimated project cost is about $1.05 billion.

Additional Sewage Rising Main and Rehabilitation of the Existing Sewage Rising Main between Tung Chung and Siu Ho Wan

The sewage rising main between Tung Chung and Siu Ho Wan is the only pipe for conveying sewage in the area. In view of the government’s development plan to expand Hong Kong International Airport and Tung Chung New Town, increase in sewage is expected and it may impose great burden on the sewage rising main. Thus, we are planning to construct a new sewage rising main in stages to cope with the situation. Meanwhile, as the existing sewage rising main is approaching the end of its design lifespan of 25 years, inspection and rehabilitation measures are carried out regularly to ensure that it is capable of handling the projected sewage flow until 2038.

Current Progress

Construction is implemented in two phases and work commenced in August 2016. Total estimated project cost is about $1.36 billion. The first phase includes the construction of a sewage rising main about 6.5 kilometres in length and 1,200 millimetres in diameter, and implementing associated connection and ancillary works. This phase is expected to be completed by 2022. The second phase that involves rehabilitating the existing sewage rising main is scheduled for completion in 2025.

The new sewage rising main

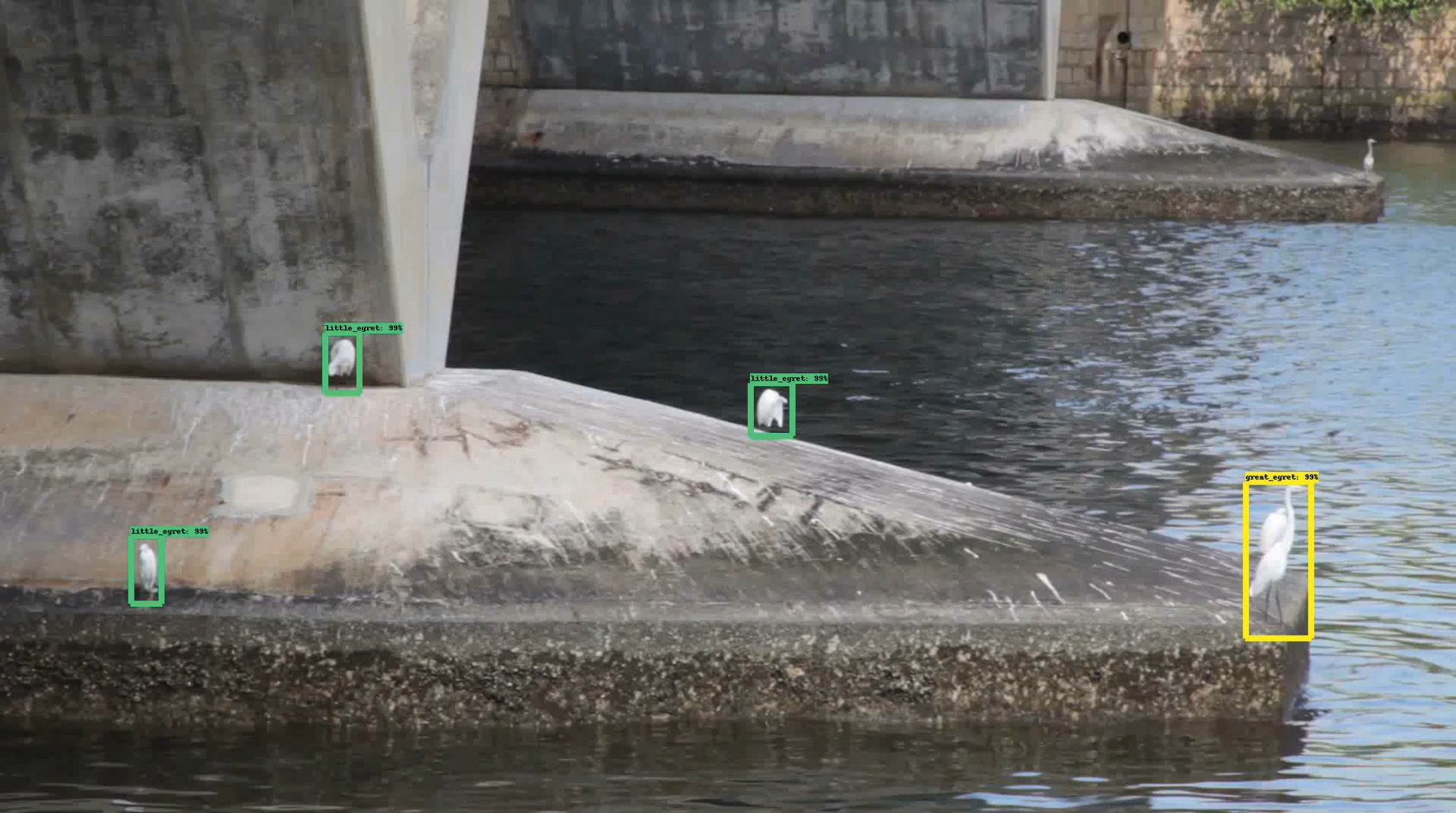

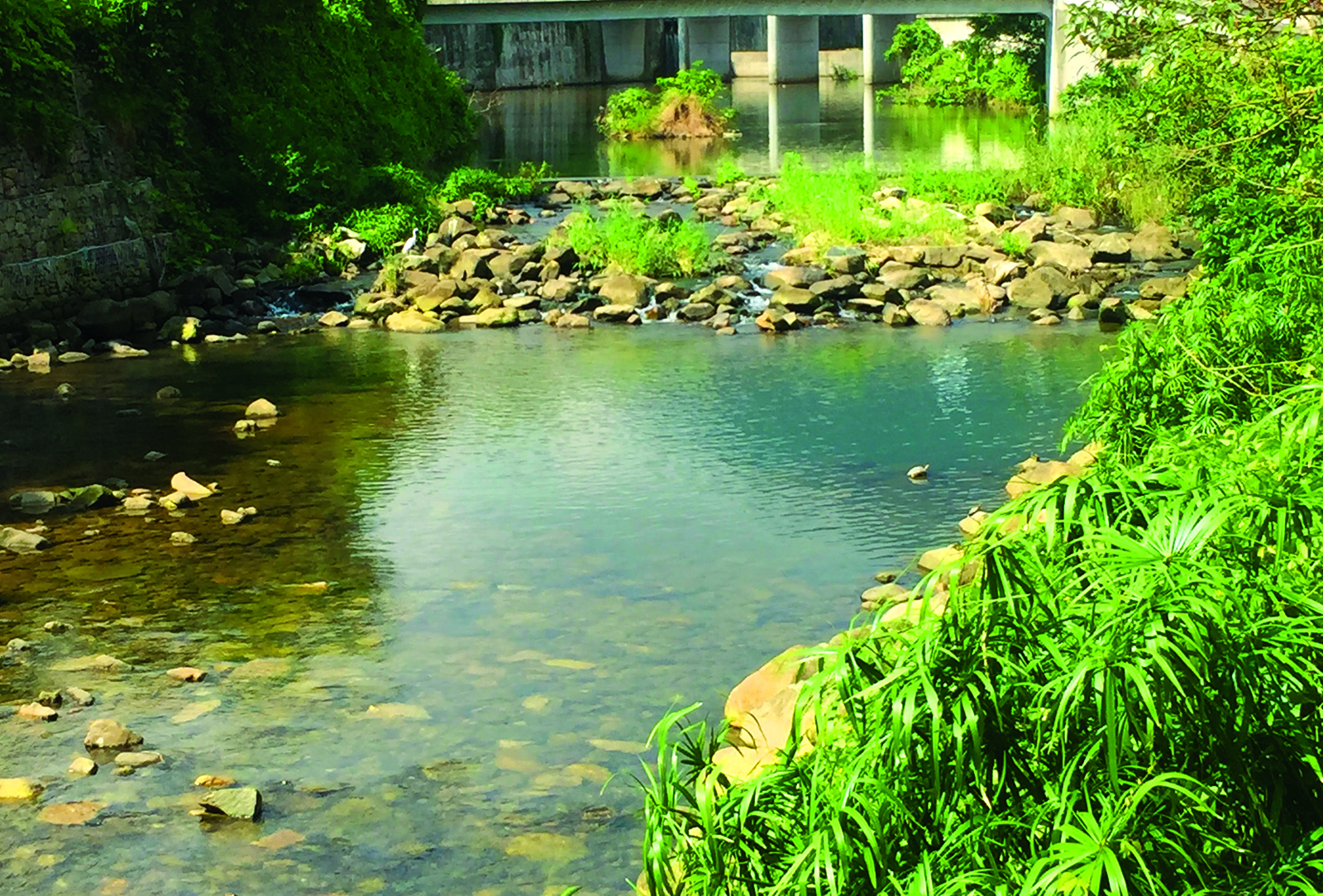

Improvement of Village Sewerage

We realise that rural areas of Hong Kong are facing the threat of water pollution. A number of villages in Hong Kong are still relying on septic tanks for sewage treatment today due to lack of public sewerage systems for proper handling of sewage from these rural communities. When not properly maintained, septic tanks may result in sewage being discharged into the stormwater drainage system, polluting surrounding water bodies and destructing the ecosystem. Thus, the DSD has endeavoured to expand its network of public sewerage system by building public sewerage in villages in Sai Kung, Northern District, Kwun Tong, Yuen Long, Sha Tin, Tai Po, Tseung Kwan O, Tuen Mun and the Outlying Islands to collect and treat sewage from these areas. These works have minimised the pollution problem brought by improper sewage disposal.

Sewer laying at a village

Current Progress

As at March 2021, newly built public sewers were in place in more than 250 villages; works were in progress in around 55 villages; and sewers were under planning and design for about 230 villages. The latter include sewerage construction works for the Outlying Islands District. In the fourth quarter of 2021, DSD will commence two projects to provide sewerage for parts of Lamma Island and Lantau Island to improve sanitary conditions and further reduce the amount of pollutants being discharged into nearby stream courses and marine waters. These two projects are scheduled for completion in 2026 at a total estimated cost of about $0.6 billion.

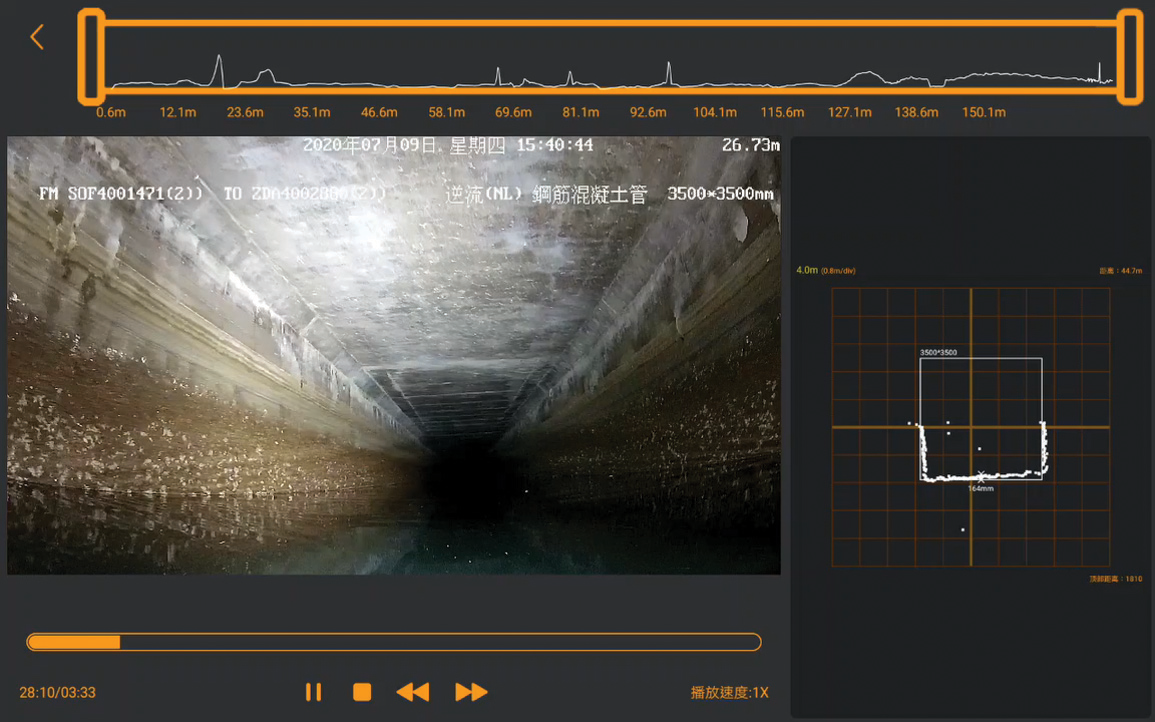

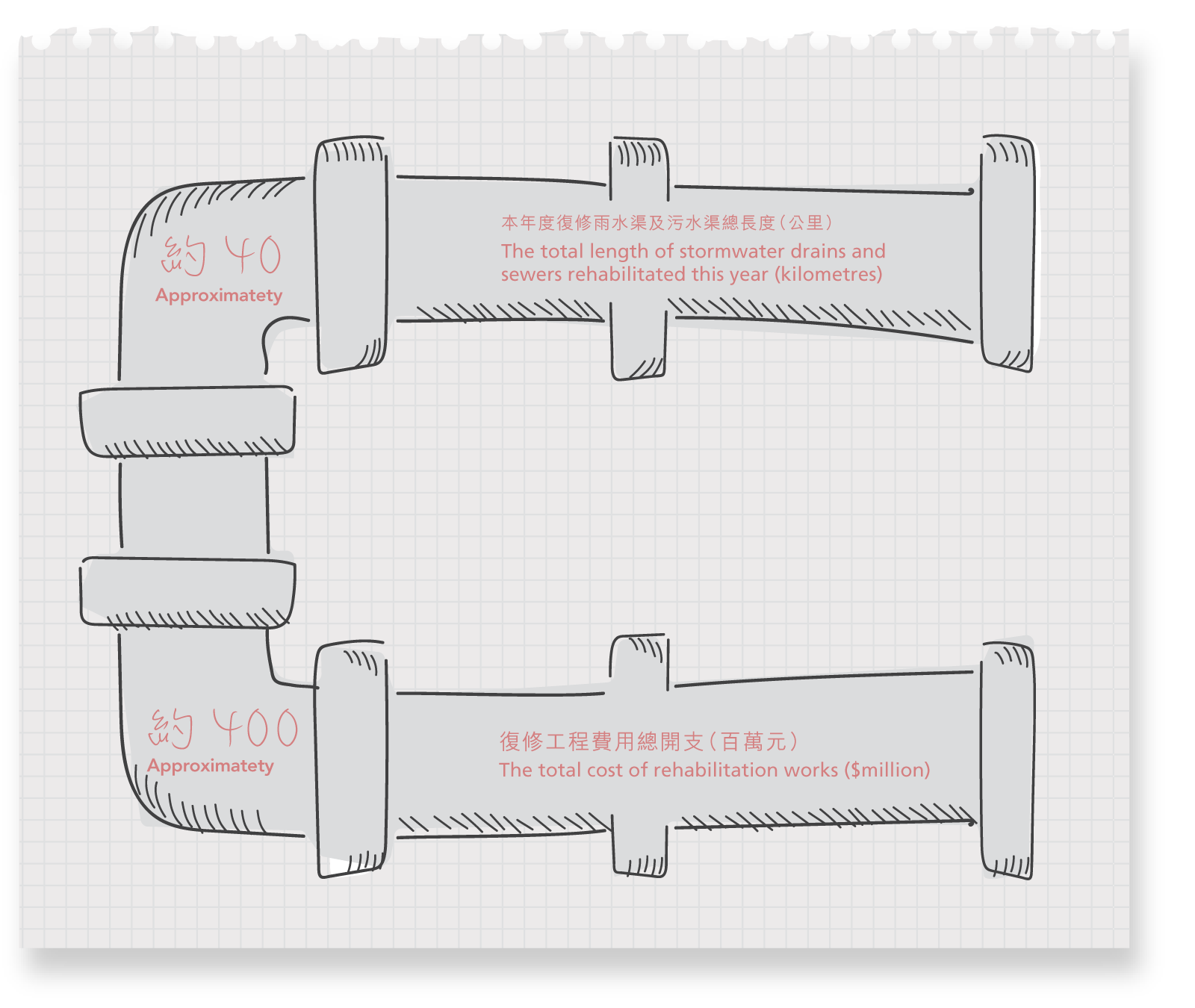

Managing Drainage and Sewerage Networks

The DSD manages approximately 4,700 kilometres of drainage system across Hong Kong. Some of the underground pipes have been in service for 30 years on average while over 2,200 kilometres of pipes having been in use for 30 years or longer. Many of them are showing signs of ageing and wear and tear. Seriously deteriorated pipes may result in structural failure, followed by soil erosion and even road subsidence, affecting normal operation of the pipelines and bringing adverse impacts on traffic, environment and public safety.

To prevent environmental and public safety risks caused by deteriorated pipes, the DSD is sparing no effort in the repair and maintenance of pipes. We have launched a territory-wide risk-based rehabilitation programme for aged stormwater drains and sewers, under which surveys and rehabilitation of high-risk underground pipes are being conducted in phases. We will also examine and employ various cutting-edge technologies to efficiently maintain our underground pipe networks and enhance the cost-effectiveness of our works.

Rehabilitation of Trunk Sewers in Kowloon, Sha Tin and Sai Kung

Apart from the above works, the DSD is also carrying out rehabilitation works to four sections of trunk sewers totalling 1.7 kilometres in length in Ngau Chi Wan, To Kwa Wan, Sha Tin and Sai Kung respectively, as well as constructing about 0.6 kilometres of additional trunk sewers and undertaking related sewage diversion and manhole rehabilitation works in Sha Tin and Sai Kung. These works aim to enhance the reliability of our sewerage system and reduce the risk of sewer collapse and sewage seepage for the sake of public safety and environmental hygiene.

Sewer manhole rehabilitation works

Current Progress

Trenchless construction of new trunk sewers was completed by using micro-tunnel boring machines. We have rehabilitated 90% of the sewers to date while maintaining the services of the sewerage system. Works commenced in January 2018 and are scheduled for completion in the first quarter of 2022 at an estimated project cost of approximately $680 million.

Rehabilitation of Trunk Sewers in Tuen Mun

We have identified signs of ageing and deterioration in about 4.2 kilometres of existing trunk sewers along Tin Hau Road and Lung Mun Road, Tuen Mun during inspection. That sewer section has been in service for over 40 years. Currently, we are carrying out rehabilitation of the trunk sewers as well as two inverted siphons underneath Tuen Mun River near Tin Hau Road and Tuen Yee Street. We are also constructing about 0.6 kilometres of new trunk sewers. The project aims to reduce the risk of sewage seepage and collapse, enhance public safety and environmental hygiene and improve the operation reliability of the sewerage system.

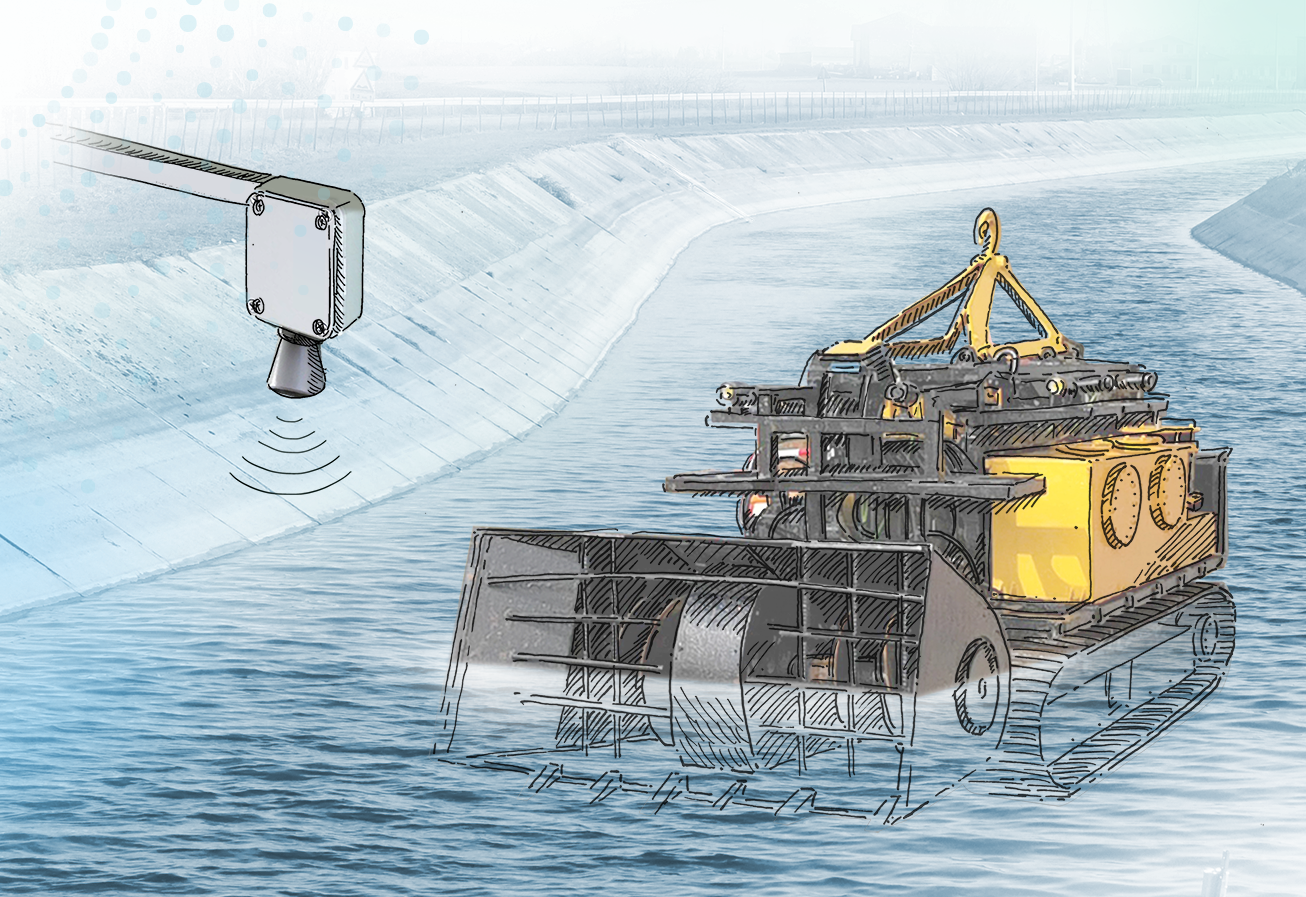

Deploying robotic machine for lining installation works in existing box culvert with live sewage flow

Adopting trenchless construction technology and using micro tunnel boring machines to lay sewage pipes

Current Progress

The DSD is using trenchless technology to rehabilitate trunk sewers and using micro tunnel boring machines to construct new trunk sewers. Robotic machines are also deployed to carry out lining installation in the existing box culverts with live sewage flow in an innovative way. This approach promotes efficiency and minimises safety risks faced by workers in confined space. The works commenced in December 2018. About 32% of the existing sewers have been rehabilitated and about 90% of the sewers have been constructed. The project is scheduled for completion in the first quarter of 2023 at an estimated cost of about $806 million.