Disinfection

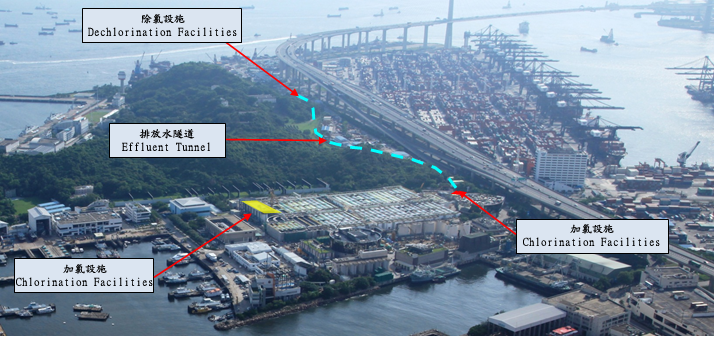

After the CEPT process, the effluent is convey to the flow distribution chamber where bleach (sodium hypochlorite) is added for disinfection. The effluent undergoes disinfection process in the new Effluent Tunnel to reduce over 99.9% of E-Coli in the treated effluent. The effluent then undergoes a dechlorination process at Chamber 15A where sodium bi-sulphite is added to neutralize the residual chlorine before discharging to the Southwest part of Stonecutters lsland. Chlorination technology is selected for disinfecting the HATS effluent after undertaking a very vigorous EIA study to provide the most proven, reliable, flexible, cost effective and environmentally acceptable option for HATS. The Advance Disinfection Facilities has been satisfactorily operating since March 2010 to facilitate the early re-opening of the closed Tsuen Wan Beaches. In order to cope with the increased treatment capacity of SCISTW, the Final Disinfection Facilities commissioned in January 2016. The Final Disinfection Facilities increase the chlorine contact time which could streamline the disinfection process.