Our Department endeavours to employ advanced technology to provide local residents a comprehensive sewage treatment service of a world-class standard. With advanced wastewater treatment technology, we have removed substantial amount of pollutants from wastewater. Our environmental conscientiousness has prompted us to also recycle wastewater.

Our Sewage System

The Department has developed an extensive sewerage network that covers the entire Hong Kong; the total length is about 1647 kilometres, almost the distance from Hong Kong to Jinan, Shandong. Our sewerage system serves 93 per cent of the Hong Kong population.

Currently, we are operating 287 sewage treatment facilities, including 68 STWs and 219 sewage pumping stations. On average, we treat 2.69 million m3 of sewage collected from our network every day.

| Summary of Sewage Treatment Facilities and Sewerage Network | 2009-2010 | 2010-2011 | 2011-2012 |

| Annual sewage treatment capacity (million m2) | 979 | 979 | 981 |

| Coverage of public sewerage (population percentage) | 93% | 93% | 93% |

| Total length of sewerage network (km) | 1622 | 1637 | 1647 |

| Total number of sewage treatment facilities | 277 | 284 | 287 |

In 2011-12, we treated 981 million m3 of sewage in total; 29.2 per cent of the sewage received preliminary treatment, 53.5 per cent chemically enhanced primary treatment, and 16.9 per cent secondary and tertiary treatments. The remaining less than 0.4 per cent received preliminary and tertiary treatments.

Sludge is produced during the sewage treatment process. The total quantity of sludge collected in 2011-12 was 301347 tonnes. It required about 25882 container vehicle trips to deliver this amount of sludge to the landfills for disposal.

We continue to maintain our sewage collection, treatment and disposal facilities to ensure an efficient operation. We strive hard to continue to improve the sewerage coverage and treatment facilities in line with the sustainable development of Hong Kong.

Our team of professionals, employing advanced technologies and managing our first-class facilities, always endeavours to provide sewage collection and treatment services of a world-class standard.

An overview of Shatin Sewage Treatment Works (STW)

Sewage Treatment Performance

Our Laboratory is committed to providing a professional and a high standard of laboratory services to control and monitor the performance of our STWs.

We have set a series of strict quality objectives to monitor our performance. In 2011-12, we achieved full compliance, meeting all of the set targets.

Quality Objectives for Effluent Control

| Quality Objectives | Target | Result | Compliance |

| Effluent discharge standard | 94.7% | 99.9% | |

| Completion of effluent analysis according to the discharge licences | 100% | 100% |

Professional Laboratory Services

Strict quality compliance relies on the support from our Laboratory. Our Shatin Central Laboratory has gained accreditation since 1999 for testing environmental samples (water and wastewater) under the Hong Kong Laboratory Accreditation Scheme, operated by the Hong Kong Accreditation Services of the Innovation Technology Commission. In the period between 1999 and 2012, the number of tests accredited increased from 7 to 17. The testing parameters accredited so far are listed as follows:

| Year | Tests Accredited | Total Number |

| 2011-2012 |

Total Suspended Solids (TSS) Biochemical Oxygen Demand (BOD) Chemical Oxygen Demand (COD) Ammonia Nitrogen Nitrite Nitrogen Nitrate and Nitrite Nitrogen Total Kjeldahl Nitrogen Total Solids pH Escherichia Coli Conductivity Total Dissolved Solids (TDS) Total Hardness Turbidity Colour Anionic Surfactants Non-ionic Surfactants |

17 |

We will continue to upgrade our testing services and standard. In 2012-13, we expect to obtain accreditation for three additional tests, namely oil and grease, chloride, and sulfate.

Analytical Services

A comprehensive sampling scheme is in place to provide pollutant loading measurement and to monitor treatment efficiency at various treatment units. This helps ensure that the quality of effluent complies with discharge licensed conditions and accurate data can be gathered for quality monitoring.

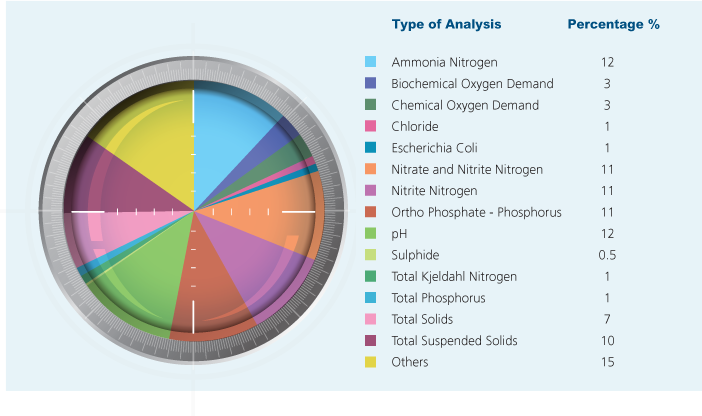

Extensive laboratory testing, covering more than 14 types of analyses, has been carried out in our laboratories in Shatin, Tai Po, Sai Kung, Shek Wu Hui and Yuen Long. In 2011-12, these laboratories carried out a total of 238340 analyses; the breakdown is as follows:

Distribution of Analyses

Progress of Major Projects

1. Harbour Area Treatment Scheme: Stage 2A

Overview

The Harbour Area Treatment Scheme (HATS) aims to improve the water quality of the Victoria Harbour by intercepting and treating sewage generated from both sides of the harbour. HATS consists of two stages and will ultimately serve a population of 5.7 million when completed. Stage 1 was commissioned in December 2001 and is now treating about 75 per cent of the sewage generated from both sides of the harbour by chemically enhanced primary treatment. Stage 2 is divided into Stage 2A and 2B. The former, now in progress, will collect and treat the remaining 25 per cent of the sewage generated from Hong Kong Island's north and southwest and disinfect all effluent before discharge. A review study is now being carried out by the Environmental Protection Department to study the implementation programme for Stage 2B. This aims to add biological treatment to the effluent. Stage 2A is targeted for commissioning in 2014-15 and will improve the effluent quality and hence the harbour water quality, while Stage 2B will further improve the quality of effluent.

Under HATS Stage 2A, the commissioned disinfection facilities at Stonecutters Island Sewage Treatment Works (SCISTW) have resulted in a significantly improved water quality at seven beaches in Tsuen Wan. The works were completed on schedule and the facilities were commissioned in March 2010. The reopening of four of those Tsuen Wan beaches took place in June 2011 and the remaining three will be reopened in the swimming season of 2013, providing the general public more locales for swimming.

We commenced the construction of the deep tunnels under the Stage 2A Sewage Conveyance System (SCS) via three main contracts in 2009. By 2011, another five major works contracts have been awarded for upgrading SCISTW and the preliminary treatment works at the northern shore of Hong Kong Island.

|

|

| Deordourisation unit of SCISTW | An image of the completed SCISTW |

Progress in 2011-2012

During the year, we continued the momentum in implementing the Stage 2A project and awarded two more major contracts for upgrading SCISTW and the preliminary treatment works at the southwestern shore of Hong Kong Island.

The SCS tunnels, from North Point via Sai Ying Pun to Stonecutters Island and from Aberdeen to Sai Ying Pun, are being constructed using the drill-and-blast method. The remaining twin tunnels, from Ap Lei Chau to Aberdeen, use the horizontal directional drilling method. All tunnelling works are now in full swing.

The major upgrading works at SCISTW include the construction of a large underground pumping station, with a 55-metre internal diameter and a depth of about 40 metres; a sewage tunnel, connecting the existing and new pumping stations; additional double-tray sedimentation tanks; new sludge de-watering facilities; a new effluent tunnel; deodorisation units; disinfection facilities; expansion and the covering of existing sedimentation tanks; a new control system and other ancillary facilities. There are also upgrading works at the preliminary treatment works at North Point, Wanchai East, Central, Sandy Bay, Cyberport, Wah Fu, Aberdeen and Ap Lei Chau. Within the year, we completed the excavation for the underground pumping station, which was time critical, and constructed the tunnel connecting the existing and new pumping stations. The first deodourisation unit was also commissioned in the year. All other works under the awarded contracts are progressing satisfactorily.

Cover for the existing sedimentation tanks will be completed in the second half of 2012 and will improve the surroundings' air quality. We aim to award a 'design, build and operate' contract in 2013 for the handling and disposal of sludge generated at SCISTW.

By 2014-15, we target to commission the HATS Stage 2A.

A bird's eye view of SCISTW

A Challenging Construction Process

Deep Tunnel Excavation

The SCS of HATS Stage 2A comprises a network of interconnected sewage tunnels and vertical shafts. The vertical shafts collect sewage from the preliminary treatment works in North Point, Wan Chai East, Central, Sandy Bay, Cyberport, Wah Fu, Aberdeen and Ap Lei Chau. The collected sewage will be conveyed to SCISTW via a total of 21 kilometres of deep tunnels with depths varying from 70 to 160 kilometres below sea level. The system essentially operates as an inverted siphon. In addition, there will be two short tunnels at Stonecutters Island; one links the existing and the new pumping stations inside SCISTW, the other conveys treated effluent from SCISTW to the outfall for submarine discharge. The former inter-connection tunnel is about 250 metres long and 40 metres underground; the latter about 880 metres in length and 90 metres underground.

A vertical cross-section of the Sewage Conveyance System

Special Excavation Techniques

Special techniques are used for the excavation of these deep tunnels and they include drill-and-blast method, horizontal directional drilling method, and ground freezing method.

We use drill-and-blast method to excavate the SCS tunnels from North Point via Sai Ying Pun to Stonecutters Island, and from Aberdeen to Sai Ying Pun, as well as the effluent tunnel at Stonecutters Island. This method is chosen because it can provide more working space for temporary support installation. The method also makes it possible for the excavated rocks to be reused as their quality has not been compromised during the process. In addition, the method yields a more controllable programme. Combining with pre-grouting, this method is more versatile in controlling groundwater during construction, especially for deep tunnels under the seabed.

Drill-and-blast method

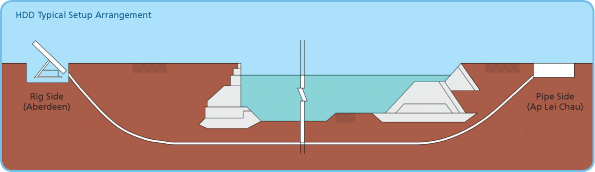

The horizontal directional drilling method is adopted for the SCS tunnel from Ap Lei Chau to Aberdeen. A drilling rig together with a set of equipment are required to change the direction of drilling and to drill a pilot hole, which is then enlarged by sequential reaming. A lining is ultimately installed inside the enlarged hole to form the tunnel.

Horizontal directional drilling

One part of the inter-connection tunnel inside SCISTW is excavated by a tunnel boring machine of the earth-pressure-balanced type, with precast concrete lining segments erected while excavating; another part is excavated by hand-mining. We choose the ground freezing method as part of the tunnel is on mixed ground adjacent to the sea, and it is necessary to prevent groundwater seepage into the tunnel and also to strengthen the ground for temporary support during excavation. Brine of calcium chloride is circulated inside pipes by pumping and cooled to about -30°C and used as coolant for freezing the ground adjacent to the tunnel during excavation.

Ground freezing method

External view of Stanley STWInternal view of Stanley STW

2. Shatin Sewage Treatment Works

Feasibility Study of Relocating Shatin STW to a Rock Cavern

Land-scarce Hong Kong, in its efforts to achieve sustainability, requires innovative approaches to its social and economic developments. With this in mind, we are studying to assess the feasibility of rehousing Shatin STW in a rock cavern. By reprovisioning suitable existing public facilities inside caverns, the Government releases sites for other uses; thus enhancing our quality of living.

Successful examples elsewhere of constructing caverns to house STWs include those from Finland, Norway and Sweden. In Hong Kong, we also have our own successful case — Stanley STW. The Stanley STW, which was commissioned in 1995, not only blends with the surrounding environment, but also minimises the environmental impact during construction and daily operation. After operating the plant for 17 years, we have gained valuable experience in managing a STW inside caverns.

Relocating Shatin STW to a cavern can release the existing 28-hectare site for housing and other purposes. The move will enhance living quality and add benefits to the local community and the environment in Shatin. We will start a feasibility study in mid-2012, the scope of which will cover preliminary technical and impact assessments, ground investigation, preparation of an outline design for the engineering works, formulation of implementation strategies and programmes, and public engagement for the relocation proposal. The study will review the suitability of Nui Po Shan at A Kung Kok as the cavern site. We will also look into the future land use of the existing Shatin STW site to assess the feasibility and cost-effectiveness of the relocation.

Proposed relocation siteStudy area for Shatin STW relocation

3. Upgrading Other Sewage Treatment Works

Mui Wo Sewage Treatment Works

The project aims to improve the water quality of Silver Mine Bay at Mui Wo. It involves the expansion of the existing Mui Wo STW to about three time its existing capacity but with only about 11 per cent increase in plant area. This is made possible by adopting the 'Membrane Bioreactor' technology. The upgrading works are scheduled to commence in mid-2012 and be completed in 2017.

Cheung Chau and Tai O Sewage Treatment Works

The project aims to improve the quality of the sea water around Cheung Chau and Tai O, both popular tourist spots. It will increase the treatment capacity and upgrade the treatment level of the existing STWs. The upgrading works are scheduled to commence in end of 2014 and be completed in stages before 2019.

Shek Wu Hui Sewage Treatment Works

The existing Shek Wu Hui STW has a design treatment capacity of 93000 m3 per day and provides secondary treatment to sewage collected from Sheung Shui, Fanling and the adjacent areas. To cope with the forecast increase in sewage flow from the local neighbourhoods and the extension of village sewerage, as well as the new developments in Fanling North and Kwu Tung North, we plan to further increase our STWs' capacity in phases. The sewage treatment will also be upgraded to tertiary level in phases in order to ensure no increase in pollution load to Deep Bay. This project will also provide an opportunity for possible re-use of treated water for toilet and other non-potable uses in Sheung Shui, Fanling and the new development areas. The first phase of expansion is planned to commence in 2015 with completion targeting for 2019-2020.

4. Extending Village Sewerage

Over the years, we have been making efforts to extend public sewerage to more villages in order to improve the sanitary conditions of the unsewered villages and the water quality of the nearby streams and water. At present, our village sewerage works at North District, Tai Po, Shatin, Yuen Long, Kam Tin, Tuen Mun, Tseung Kwan O, Sai Kung, Lamma Island, Mui Wo and South Lantau are being carried out and are under different stages of planning, design and construction. Up to March 2012, we have completed public sewerage for 146 villages while sewerage works for another 64 villages are continuing. In planning and design stage for sewerage works are another 301 villages.

Sedimentation tank of Shek Wu Hui STWAn overview of Cheung Chau STW