Staff Training and Development

We believe that training is important for both staff and the Department to provide quality services on drainage services to meet the escalating demand from the public and the growing attention for sustainability. In 2012-13, we organised a total of 278 training courses relevant to environmental and sustainability matters for our staff, in the form of induction visits, in-house training, duty visits, overseas conferences, as well as seminars and workshops.

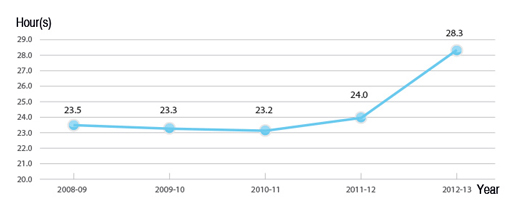

On average, our staff received about 28.3 hours of training in 2012-13. The figure is higher than the territory-wide average training hours per employee which was 19.1 hours according to the "2012 Training and Development Needs Survey" conducted by the Hong Kong Institute of Human Resource Management.

Average Training Hours per Staff

In-house Training

Staff Induction

All new comers to our Department are required to join a one-day Induction Course to enhance their understanding of the Government and the work nature of the Department, in order to foster a mindset to "serve the public" with dedication. In 2012-13, three Induction classes were held for a total of 142 colleagues.

Eurocodes

Including a series of European Standards (i.e. EN 1990 - EN 1999), the Eurocodes offer a common approach with regard to building design, other civil engineering works and construction products. In 2012-13, a number of training events on Eurocodes were organised for about 380 participants as summarised below.

| Course Title | No. of Participants |

|---|---|

| Technical Seminar on Effective Design of Steel and Steel-Concrete Composite Structures to Eurocode 4 | 2 |

| Eurocodes Seminar | 15 |

| Professional Course on Design of Reinforced Concrete Structures to Eurocode EC2 | 4 |

| Workshop on Application of Eurocodes for Design of Drainage and Sewerage Structures - Session 1 | 199 |

| Workshop on Application of Eurocodes for Design of Drainage and Sewerage Structures - Session 2 | 160 |

Occupational Safety and Health

During the reporting year, our Department has held the following training sessions regarding OHSAS 18001 Occupational Health and Safety Management System:

- Awareness Training: 20 sessions for about 1,100 colleagues (April 2012);

- Implementation Briefing: 30 sessions for about 1,700 colleagues (April - May 2012); and

- Internal Auditor Training: 7 sessions for about 160 colleagues (June 2012).

In addition to OHSAS 18001, we organised six staff training events dedicated to occupational safety and health in 2012-13, with 166 participants in total. Details are outlined below.

| Course Title | No. of Participants |

|---|---|

| Seminar on Occupational Safety and Health in Arboriculture | 15 |

| Certificate of Competence in Display Screen Equipment Assessment | 27 |

| Manual Handling Course for Managers and Supervisors | 6 |

| Basic Occupational Health and Safety Talk for Working at Sewage Treatment Works | 75 |

| Manual Lifting and Handling | 33 |

| Workshop on Occupational Health and Safety in Arboriculture | 10 |

Examples of other safety training events provided to our staff during the year include:

| Course Title | No. of Participants |

|---|---|

| Dog Bite Safety (11 Sessions) | 107 |

| One-day Training on Radiation Protection (6 Sessions) | 235 |

| Half-Day Training on Radiation Protection (7 Sessions) | 176 |

Duty Visit

Sludge Conveyance Pumping System Production Facility in Germany

In order to prevent leakage during sludge conveyance, reduce odour and enhance work safety, we planned to adopt sludge conveyance pumping system to replace the existing sludge conveyance belt in Stonecutters Island Sewage Treatment Works. To understand its production process and techniques on system testing and maintenance, our colleagues visited the system production facility in Germany in mid-October 2012. Moreover, the colleagues benefited greatly from the tours to the nearby sewage treatment works, where they learned about valuable knowledge and first-hand experience in facility operation and upholding.

Caverns Facilities in Nordic Countries

To learn from international best practices and provide reference for the feasibility study on relocation of Shatin Sewage Treatment Works to caverns, a group led by Director of Drainage Services, Mr. Chan Chi-chiu, paid a special visit to several Nordic countries in August 2012. The delegation visited a total of five sewage treatment works built inside caverns and held discussion sessions with local engineering experts. It was also learned that these sewage treatment works had integrated with the communities satisfactorily due to the implementation of a set of effective control measures.

New Engineering Contract (NEC) Attachment in the United Kingdom

In the anticipation of more upcoming New Engineering Contract (NEC) projects, our Department organised a 4-week attachment programme in the United Kingdom (in April - May 2012) for three project engineers to acquire useful knowledge of the contract management practices and collaborative working style from experienced NEC practitioners. The knowledge gained has been applied in the local NEC projects and shared amongst colleagues in our Department.

River Rehabilitation Projects in Korea and Japan

A joint duty visit by our Department, Atkins China and Mott MacDonald HK Limited was arranged to visit the river restoration and flood control projects in Korea and Japan, which was kindly supported by both Korean River Restoration Network and Japan River Restoration Network. Throughout the visit, our colleagues gained valuable knowledge in implementing river improvement works to reduce flooding risk. The areas we visited included:

- Yangjaecheon (良才川) River in Seoul

- Gyeongin Ara Waterway (京仁阿拉航道) in Seoul

- Cheonggyecheon (清溪川) in Seoul

- Sumida River (隅田河) and Old Na Ka River (舊中川) in Tokyo

- Ootoshi-furutonegawa River (大落古利根川) in Tokyo

- Koshigaya Lake Town (越谷Lake Town) in Tokyo